-

Products

-

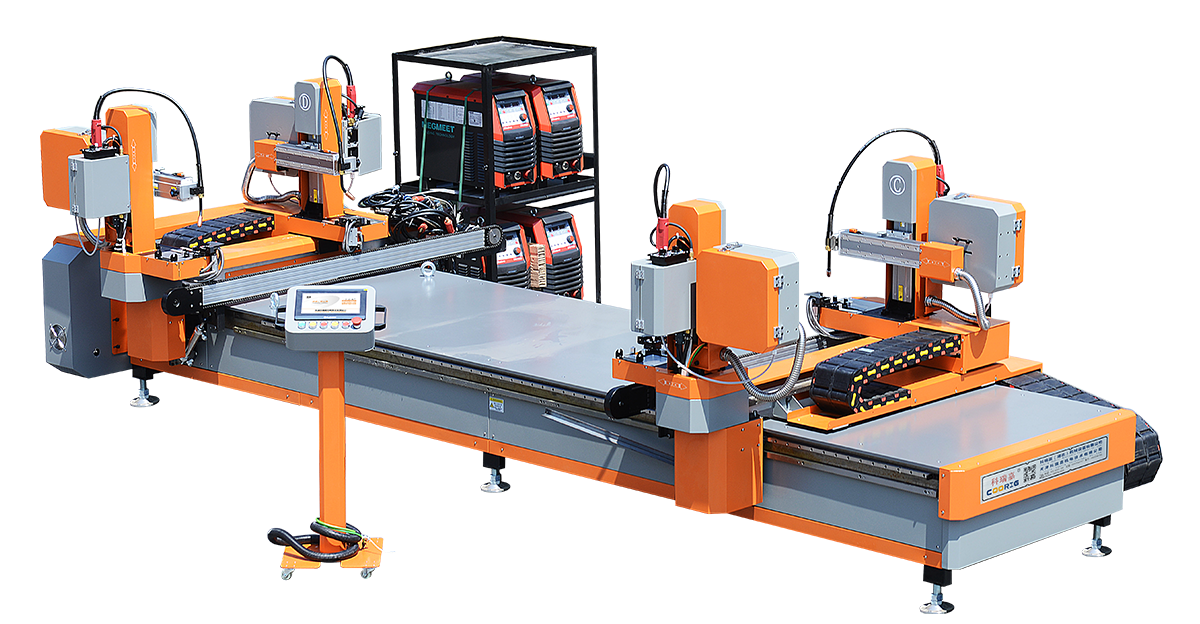

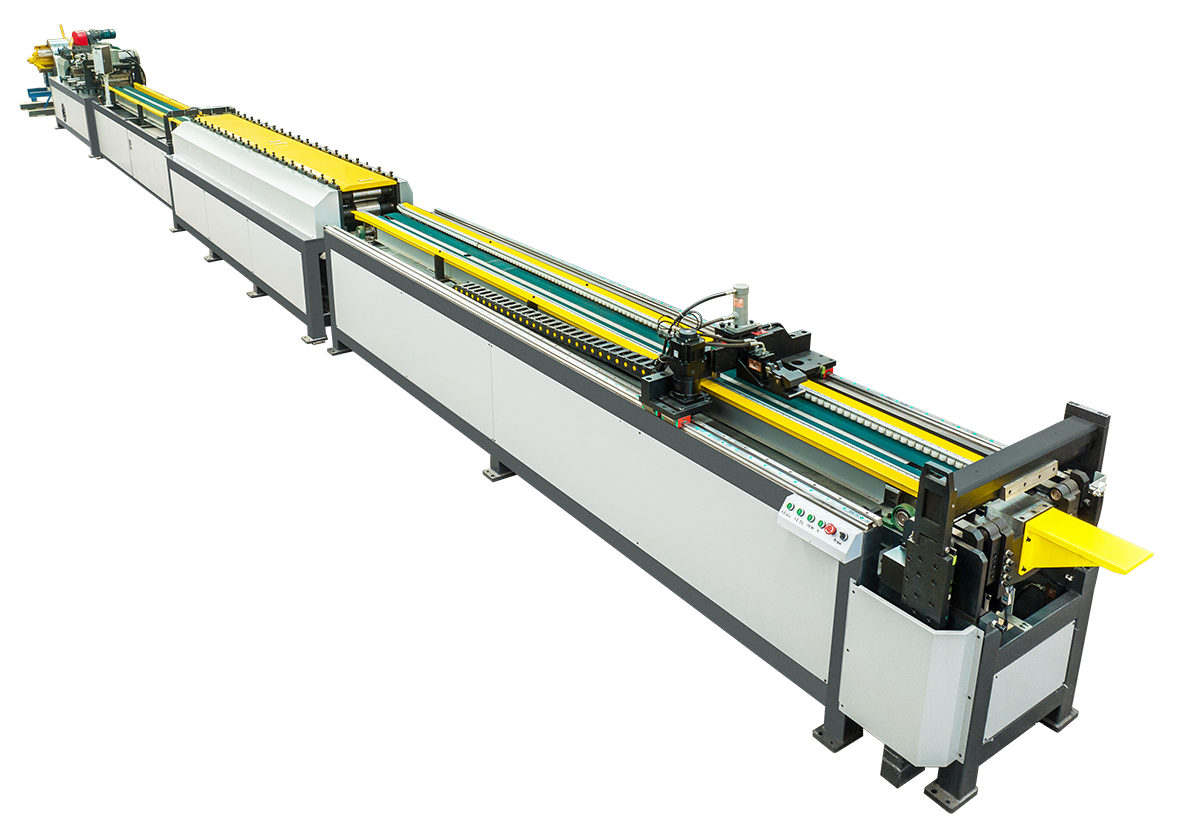

Duct Forming Production Line

-

Laser Cutting Machine Series

-

Metal Insulation Pipe Production Line

-

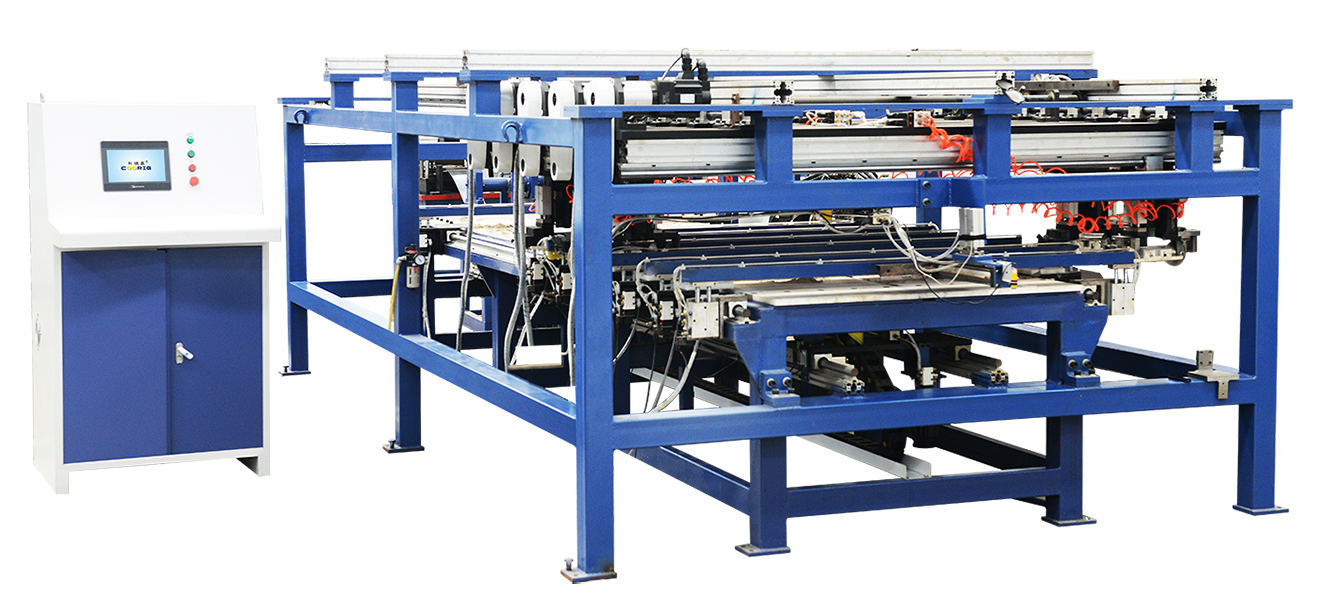

Composite Plate Duct Processing Equipment

-

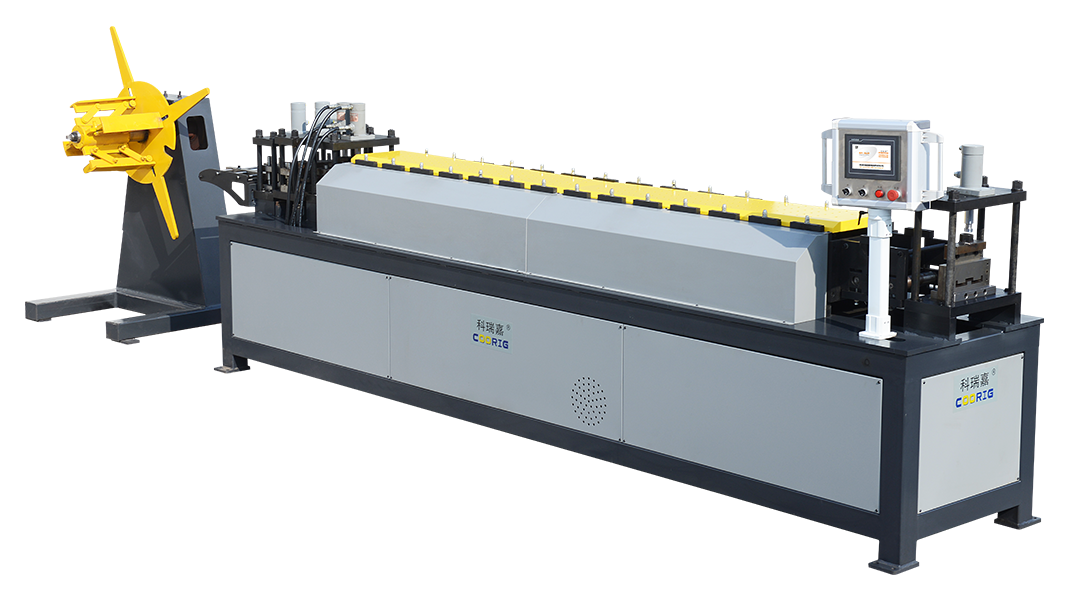

Flange Machines Series

-

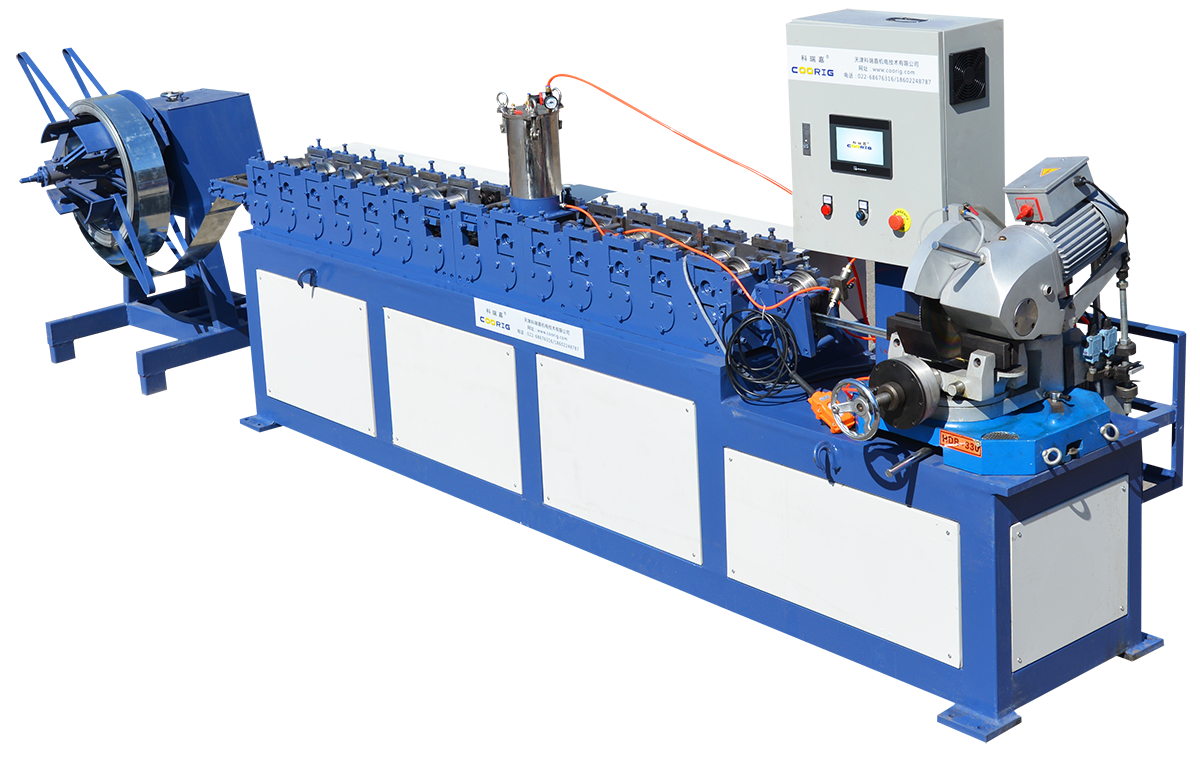

Pittsburgh Lock Forming Machine Series

-

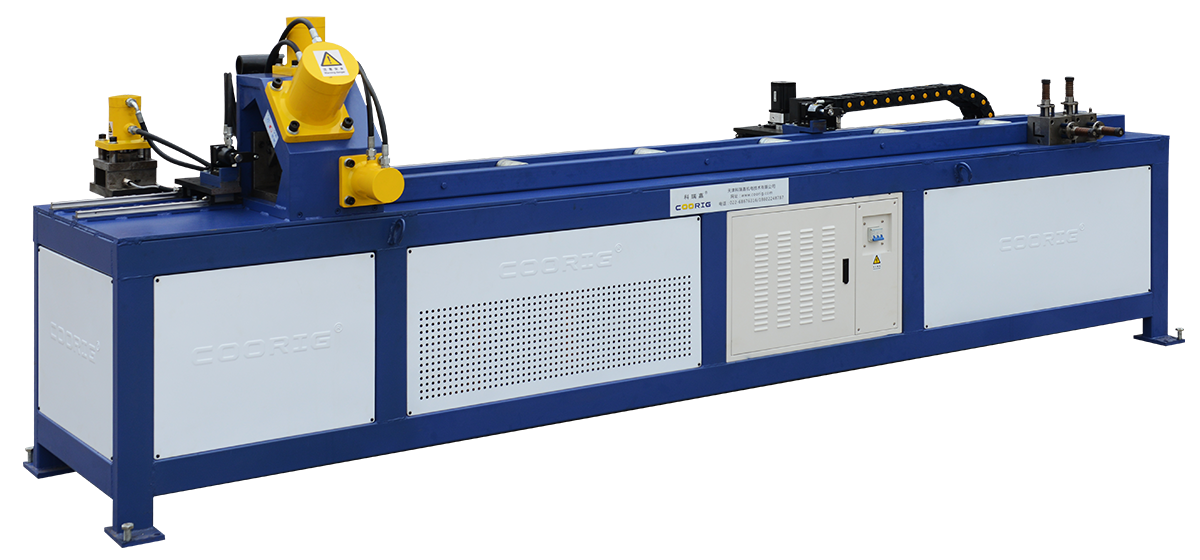

Angle Iron Flange Processing Equipment

-

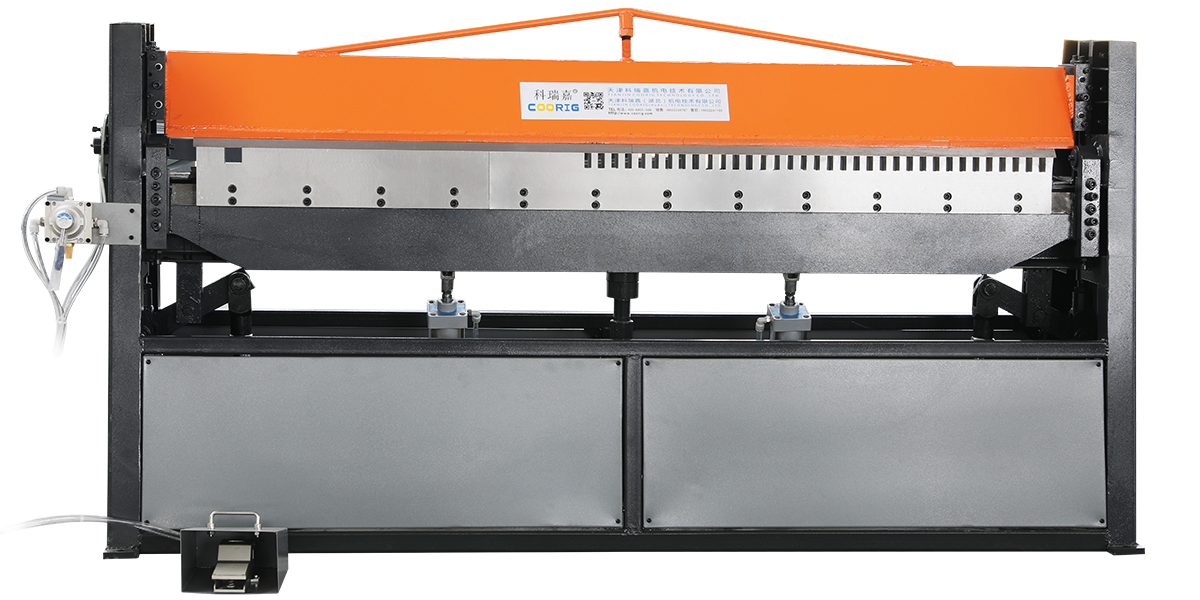

Square Duct Forming Auxiliary Equipment

-

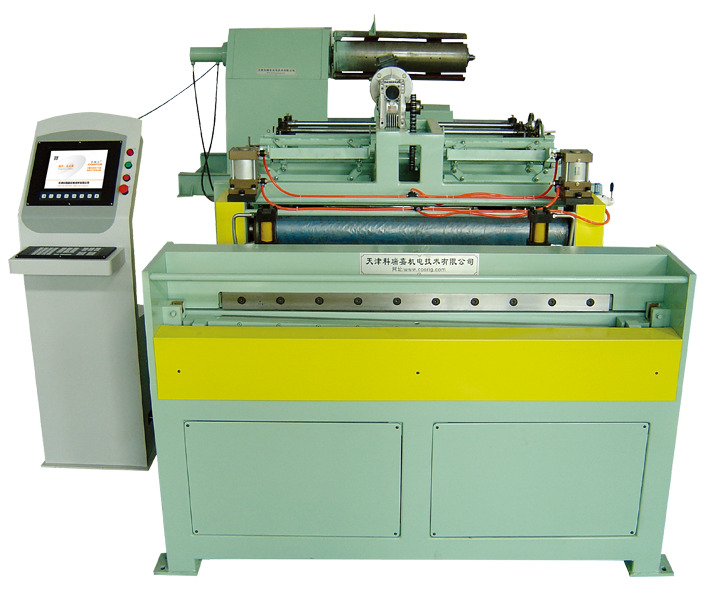

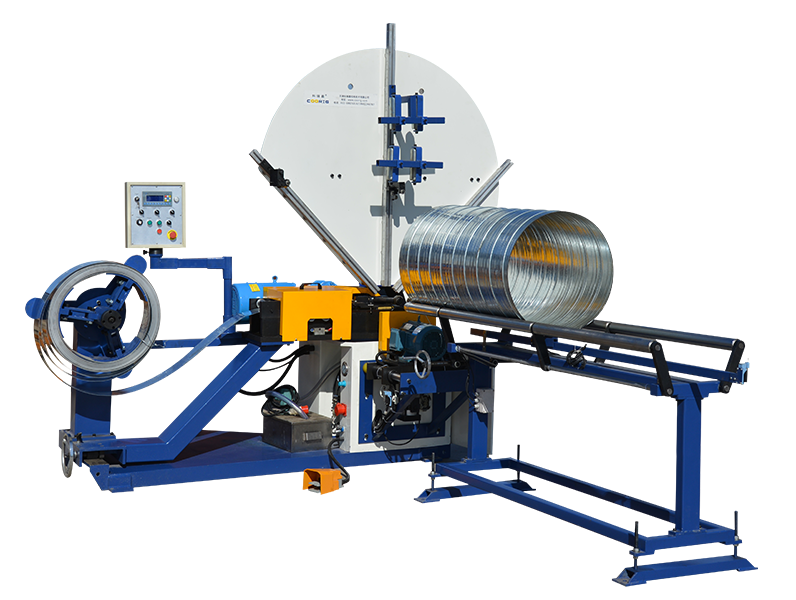

Round Duct Processing Equipment

-

Damper Processing Equipment

-

Fan Coil Equipment

-

Cable Tray Production Line

-

Fire Hose Production Line

-

Comprehensive Support and Hanger Processing Equipment

-

-

Products

Duct Forming Production Line

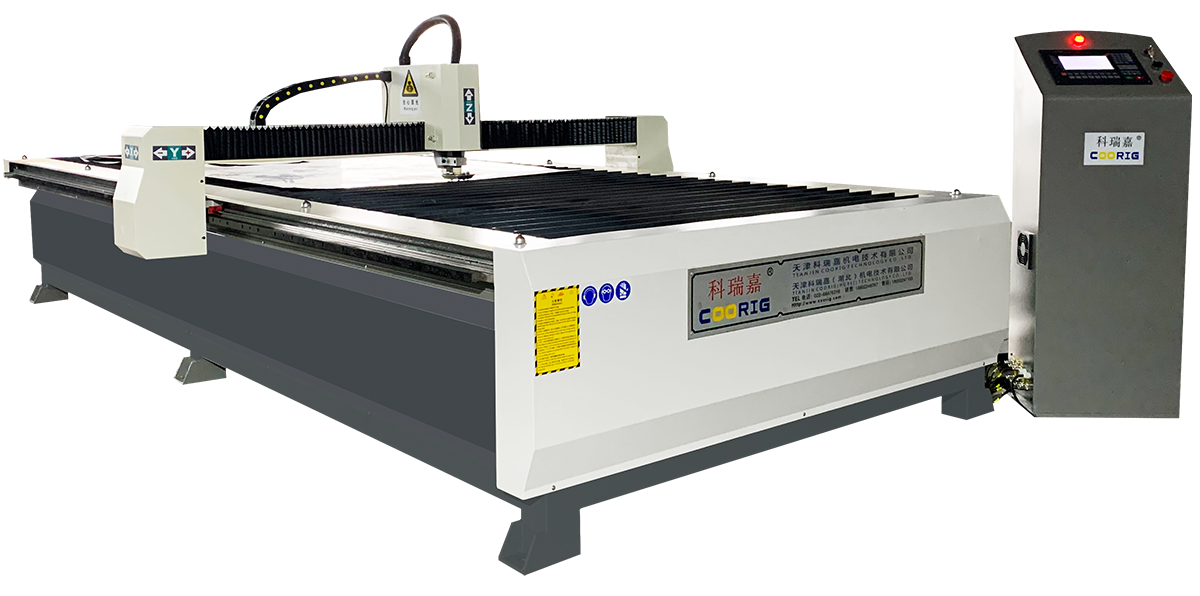

Laser Cutting Machine Series

Metal Insulation Pipe Production Line

Composite Plate Duct Processing Equipment

Flange Machines Series

Pittsburgh Lock Forming Machine Series

Angle Iron Flange Processing Equipment

Square Duct Forming Auxiliary Equipment

Round Duct Processing Equipment

Damper Processing Equipment

Fan Coil Equipment

Cable Tray Production Line

Fire Hose Production Line

Comprehensive Support and Hanger Processing Equipment

-

Application

-

Services

-

News

-

COORIG

-

Contact

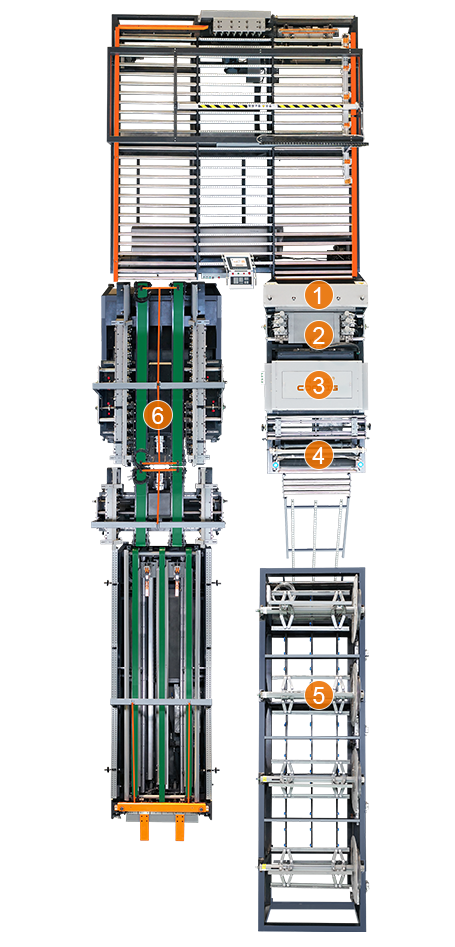

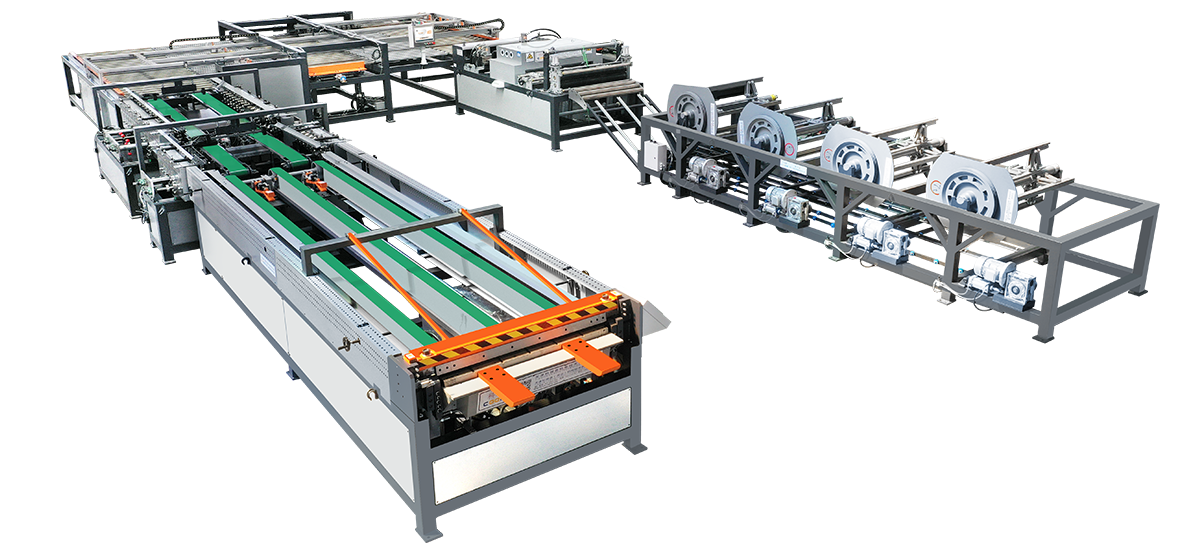

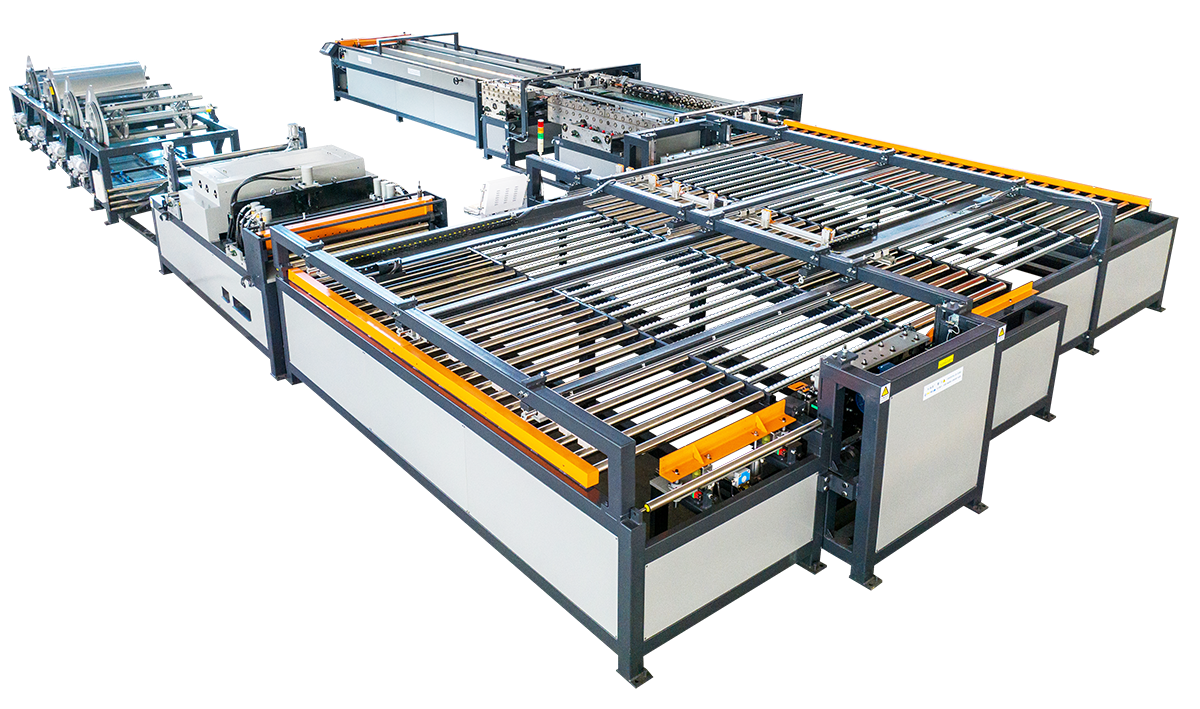

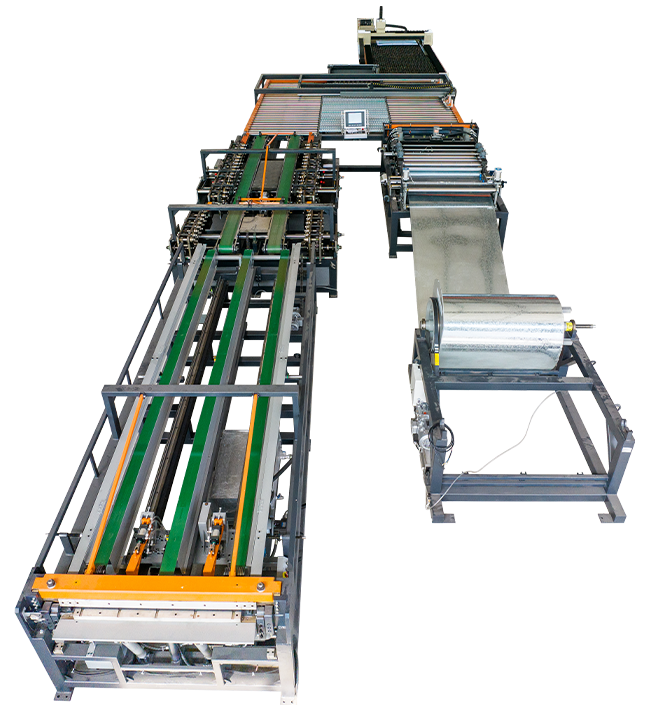

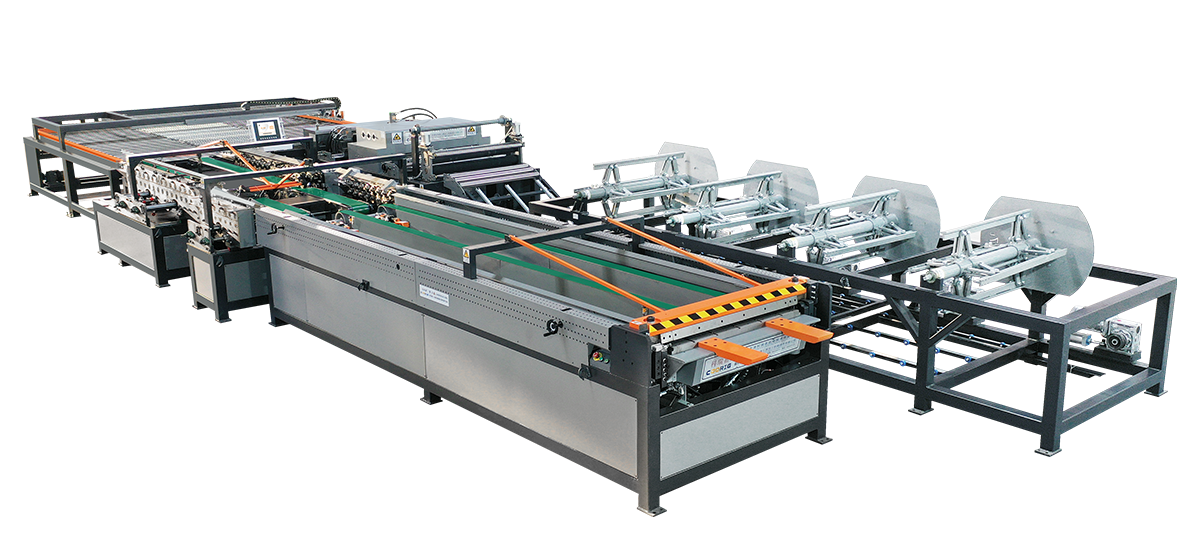

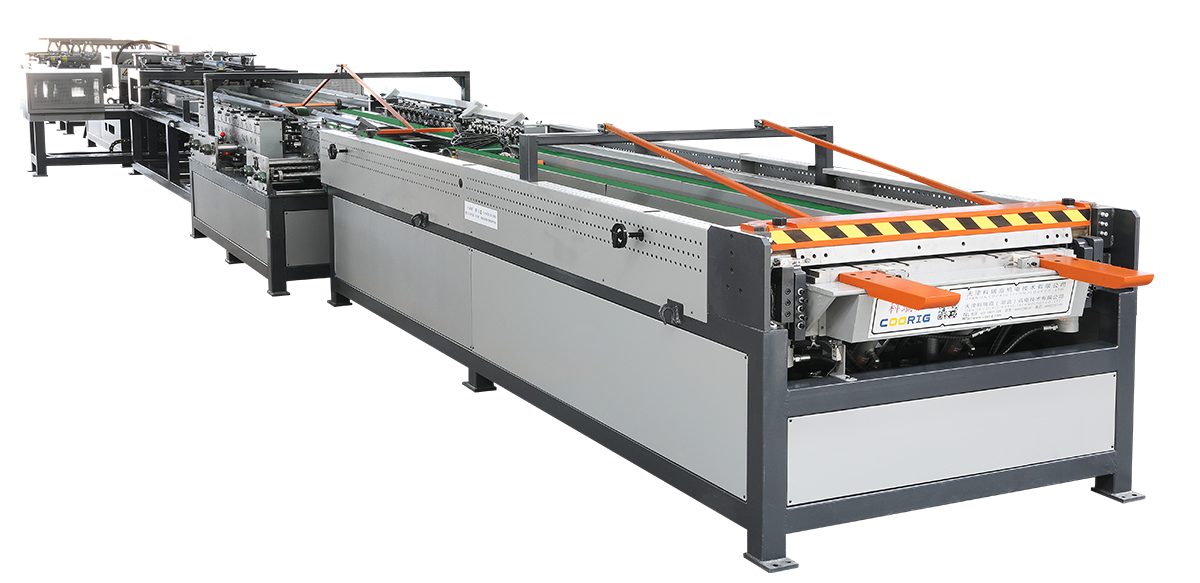

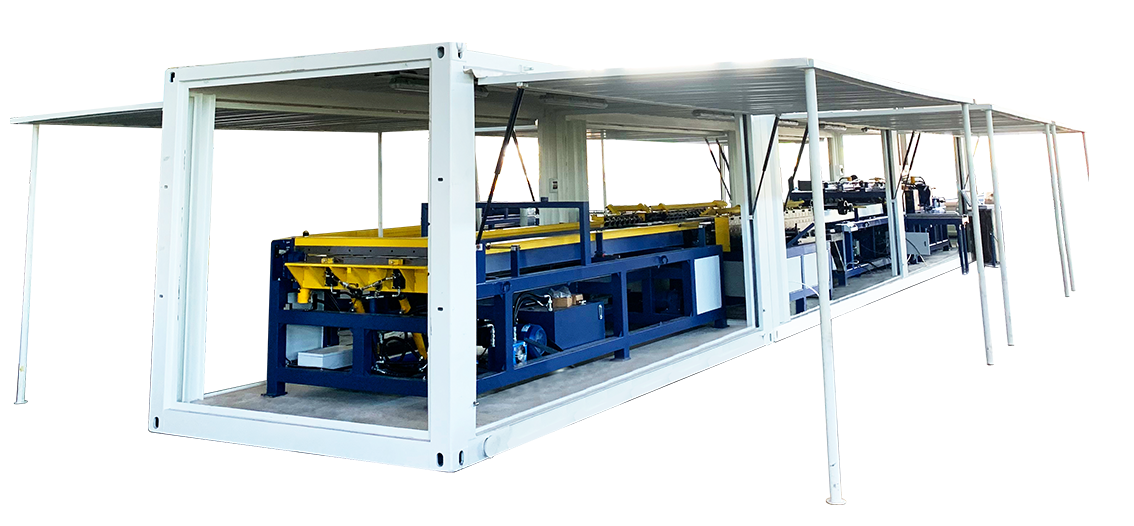

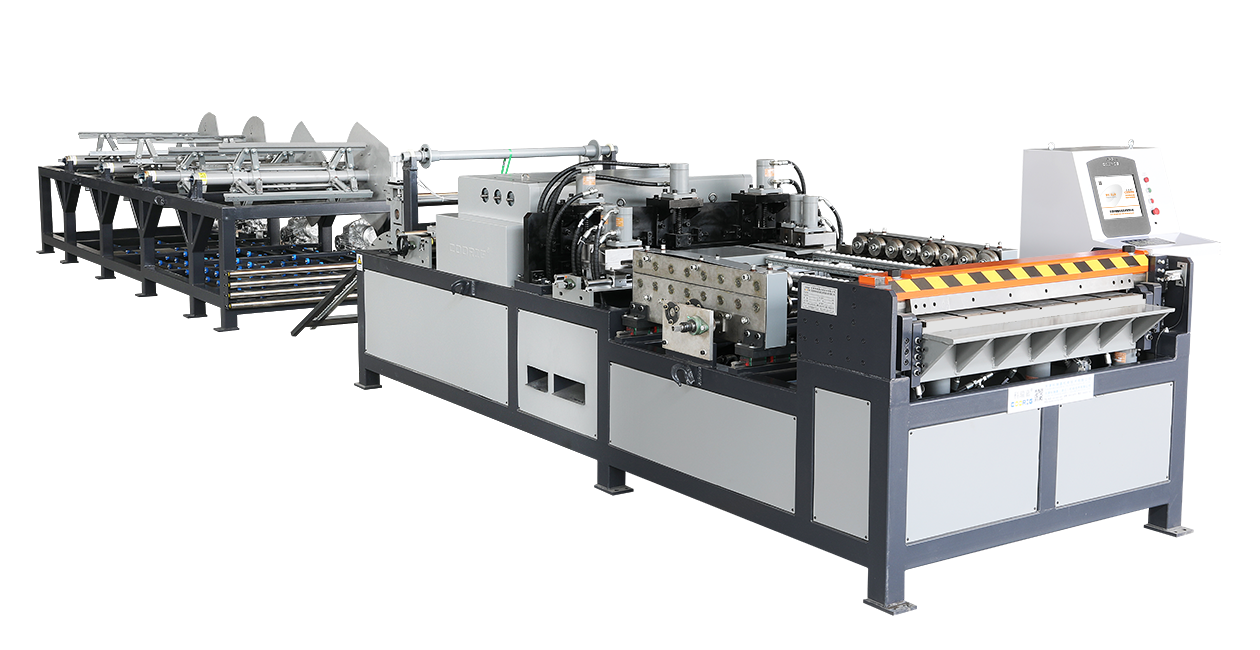

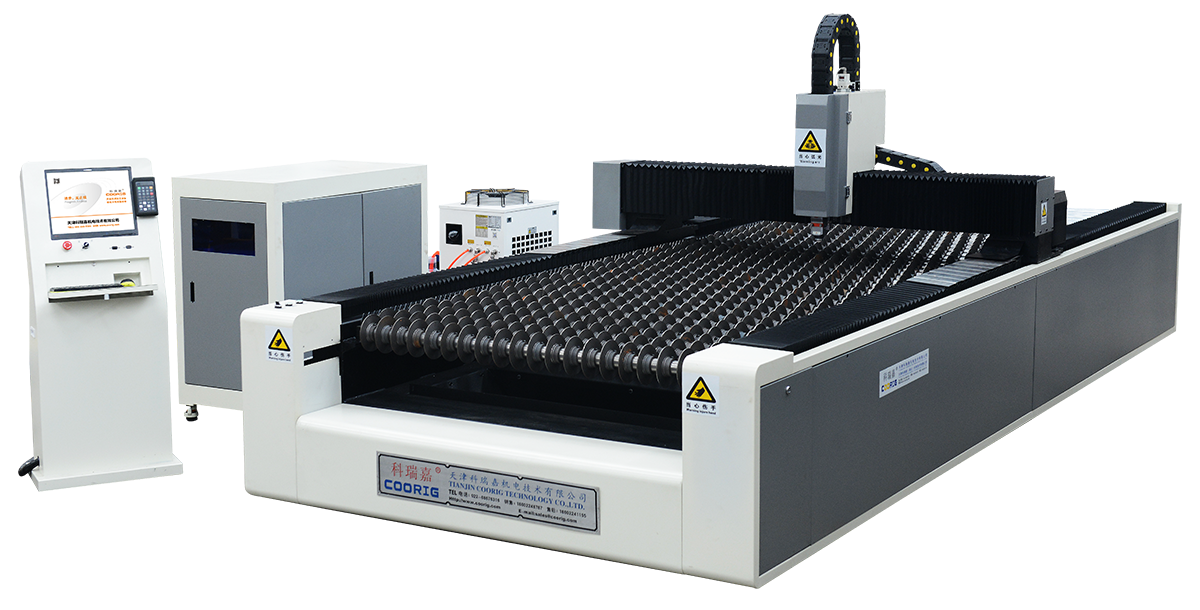

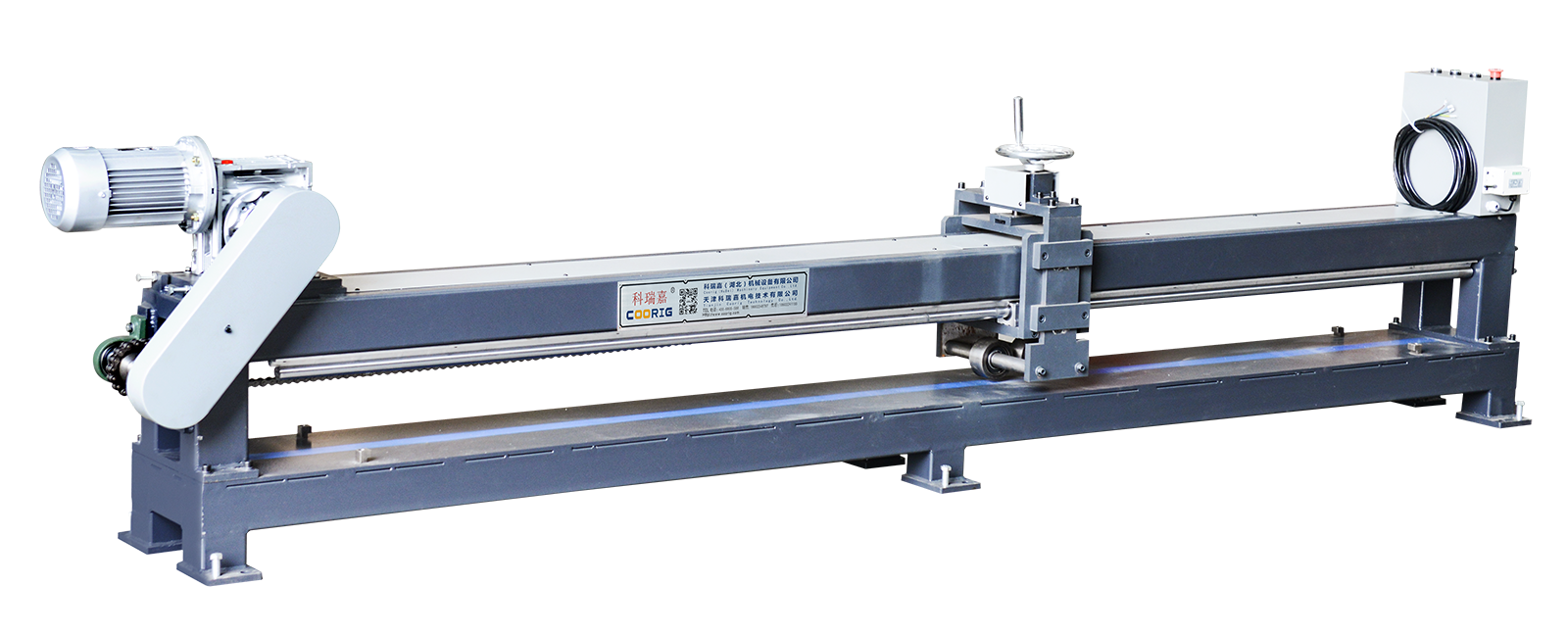

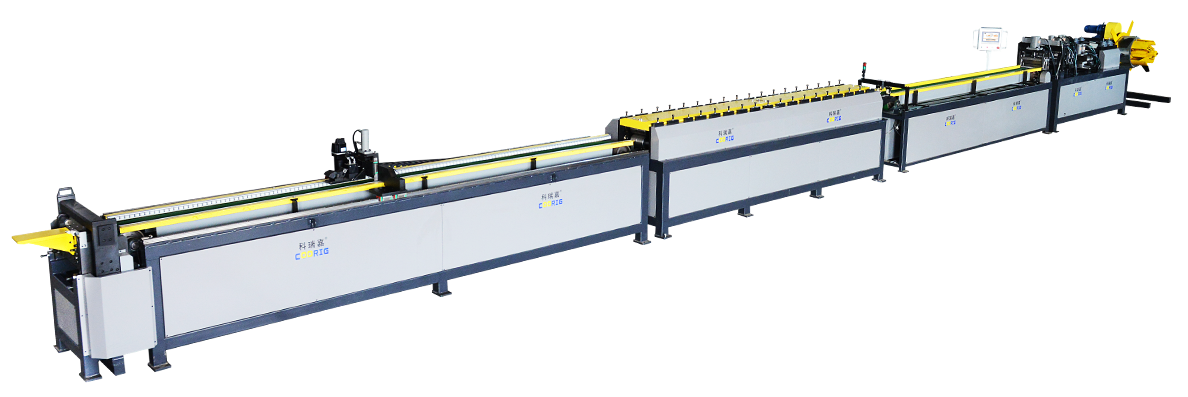

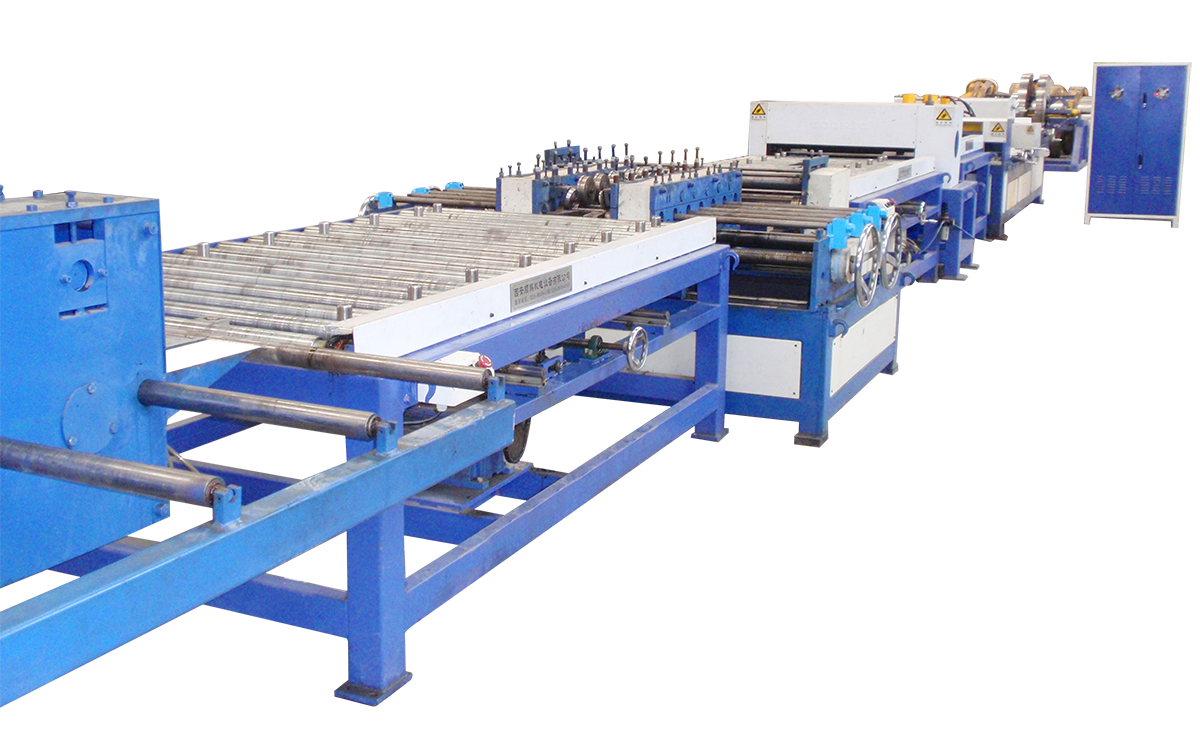

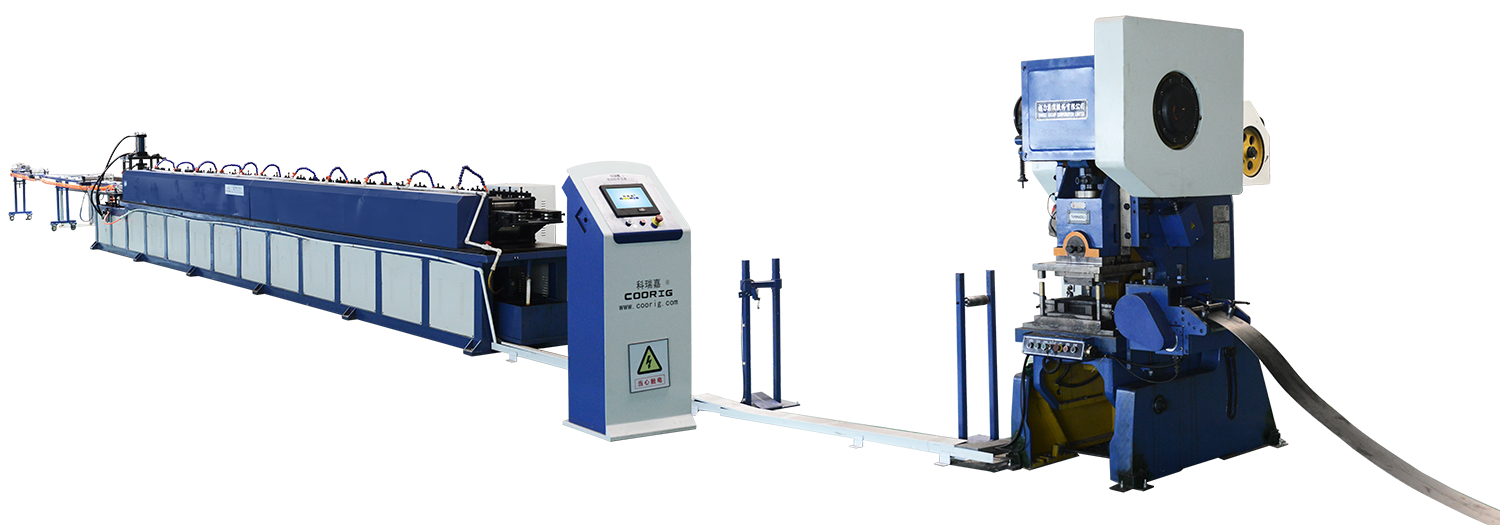

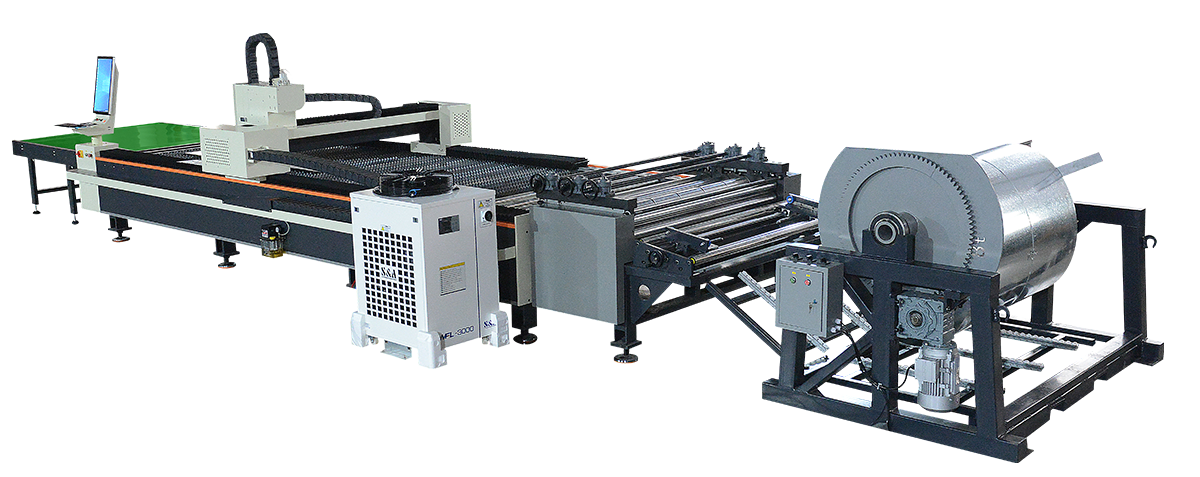

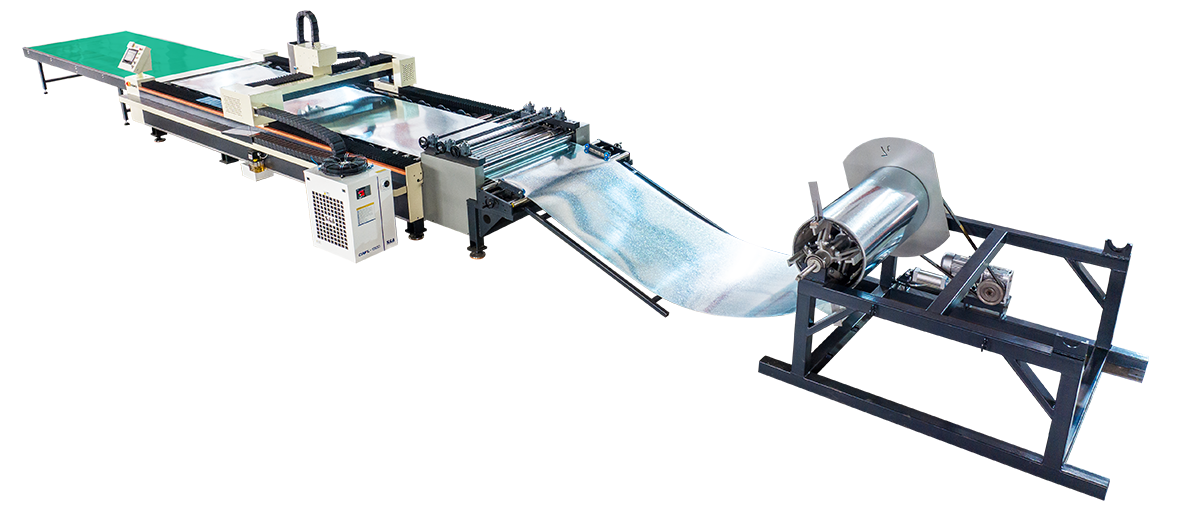

Rolling Disc Platform Laser Cutting Production Line

Environmental Protection & High Efficiency

The coil CNC adopts servo closed-loop feeding, with high feeding accuracy. The coil CNC can simultaneously control the leveling machine, rolling platform and unloading platform, it can also be independently controlled and operated separately. Supports automatic shearing after cutting is completed as well as fixed length cutting. The system has the following functions: cutting according to the drawing, precise feeding, parts jumping, automatic micro connection, automatic micro lifting, feeding single cutting at any position, whole process reverse cutting, speed regulation during processing, convenient back off etc.

FUNCTION

1. Wide range of applications, Rolling platform laser cutting machines are widely used in sheet metal processing, air duct processing, fire door production and other metal sheet cutting processing.

2. High degree of automation, realize uncoiling, leveling, beading, automatic cutting and automatic unloading linkage from the coil material, greatly improving efficiency.

3. Perfect connection with commonly used typesetting software in the ventilation industry: PM2000, CamDuck, Lantek, ProNest, FastCAM, etc., without any conversion; Support multiple format files such as ". NC", ". TXT", ". G", ". DXF", and ". DWG";

4. The system supports PM2000 and CAMDUCK automatic marking and code spraying functions (optional). 5. Optional factory wireless data communication function (optional).

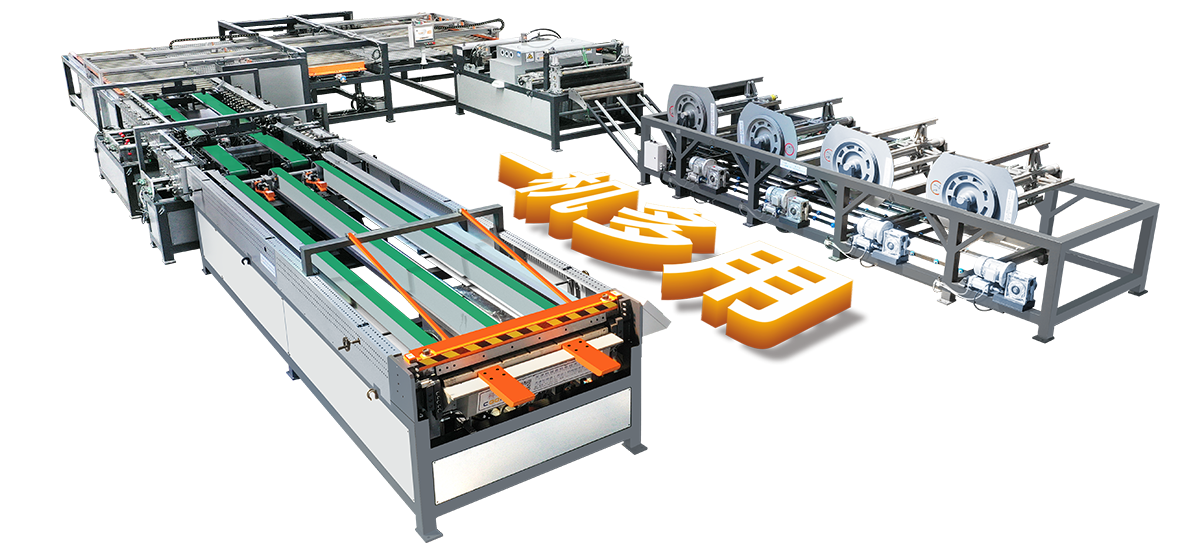

MAIN CONFIGURATION

1. A two connected decoiler (including two coilers with a maximum load of 7 tons)

2. A set of leveling and beading mechanism

3. One rolling and cutting platform

4. One unloading platform

5. One laser generator (optional power)

6. One water chiller

7. Automatic code printing (optional)

8. Remote data transmission (optional)

9. Standard roller cutting platform, optional gear hobbing cutting platform (suitable for processing small parts).

MAIN TECHNICAL DATA

|

NO. |

Model |

Capacity in

|

Maximum |

Uniaxial |

Uniaxial |

Repeat

|

Cutting speed (m/min) |

Power |

Dimensions L x Wx H (mm) |

Weight |

| 2001 | LCM-1500×4000 | Depending on generator power |

4000×1500

|

50 | 0.5 | 0.03 | Thickness range t=1mm时,V=25m/min |

Depending on generator power |

5600×2220×1700 | 2000 |

|---|---|---|---|---|---|---|---|---|---|---|

| 2002 | LCM-1500×4000-D |

Depending on

|

4000×1500 | 50 | 0.5 | 0.03 | Thickness range t=1mm时,V=25m/min |

Depending on generator power |

1000x2220x1700 | 3000 |

| 2003 | LCM-1500×4000-R |

Depending on

|

4000×1500 | 50 | 0.5 | 0.03 | Thickness range t=1mm时,V=25m/min |

Depending on generator power |

5600x2400x2060 | 4500 |

|

2004 |

LCM-1500×6000 | Depending on |

6000×1500

|

50 | 0.5 | 0.03 | Thickness range t=1mm时,V=25m/min |

Depending on generator power |

7730×2220×1700 | 3000 |

| 2005 | LCM-1500×6000-D |

Depending on

|

6000×1500 | 50 | 0.5 | 0.03 | Thickness range t=1mm时,V=25m/min |

Depending on generator power |

4000x2220x1700 | 4000 |

| 2006 | LCM-1500×6000-R |

Depending on

|

6000×1500 | 50 | 0.5 | 0.03 | Thickness range t=1mm时,V=25m/min |

Depending on generator power |

7600x2400x2060 | 55000 |

The equipment appearance, configuration and technical parameters are for reference only, the actual products shall prevail.

|

||||||||||

-

- HEADQUARTERS

- TIANJIN COORIG TECHNOLOGY CO.,LTD

- Add: Jinghai Developing Zone of Tianjin, China

- Tell: +86 022-68676316 / 68676317 / 68676318

- E-mail: forest@coorig.com

- PRODUCTION BASE

- HUBEI COORIG TECHNOLOGY CO., LTD

- Add: Fengridadao,Developing Zone of Chongyang,Hubei, China

- Tell: +86 0715-3300166 / 3300566

- E-mail: forest@coorig.com

-

- Products

- Duct Forming Production Line

- Laser Cutting Machine Series

- Metal Insulation Pipe Production Line

- Composite Plate Duct Processing Equipment

- Flange Machines Series

- Pittsburgh Lock Forming Machine Series

- Angle Iron Flange Processing Equipment

- Square Duct Forming Auxiliary Equipment

- Round Duct Processing Equipment

- Damper Processing Equipment

- Fan Coil Equipment

- Cable Tray Production Line

- Fire Hose Production Line

- Comprehensive Support and Hanger Processing Equipment

- Services

- After-Sale Service

- Service Network

- Application

- Customer Site

- Video Center

-

WeChat Official Account

-

Mobile Browsings