-

Products

-

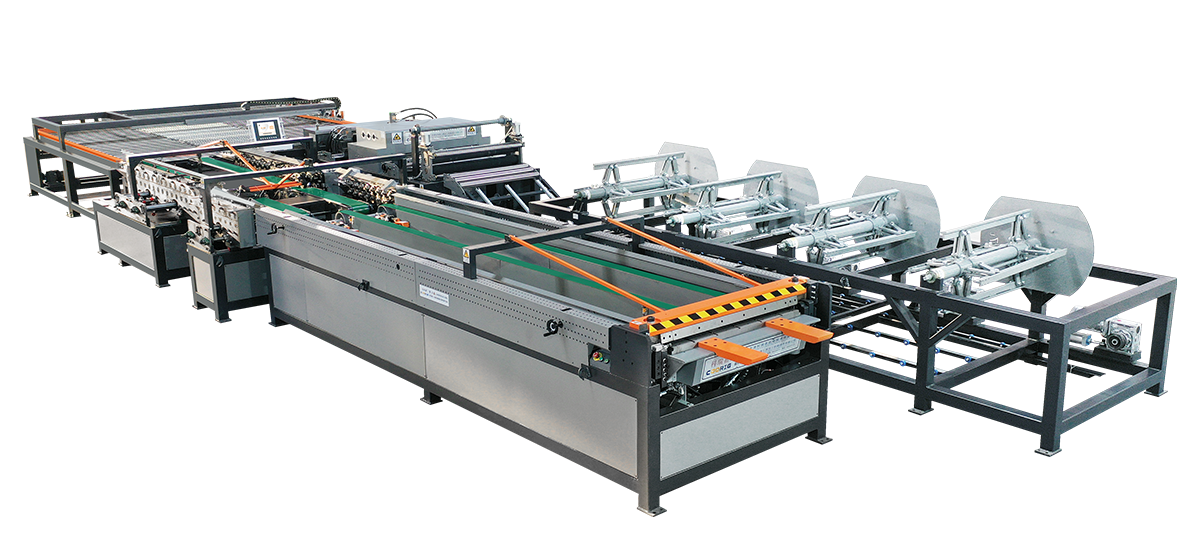

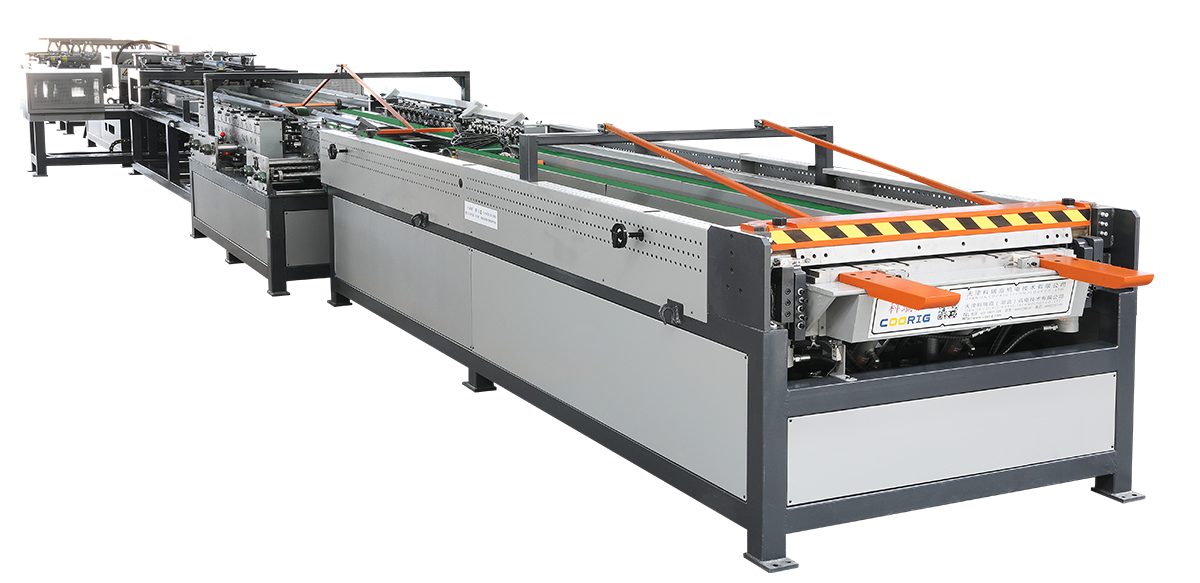

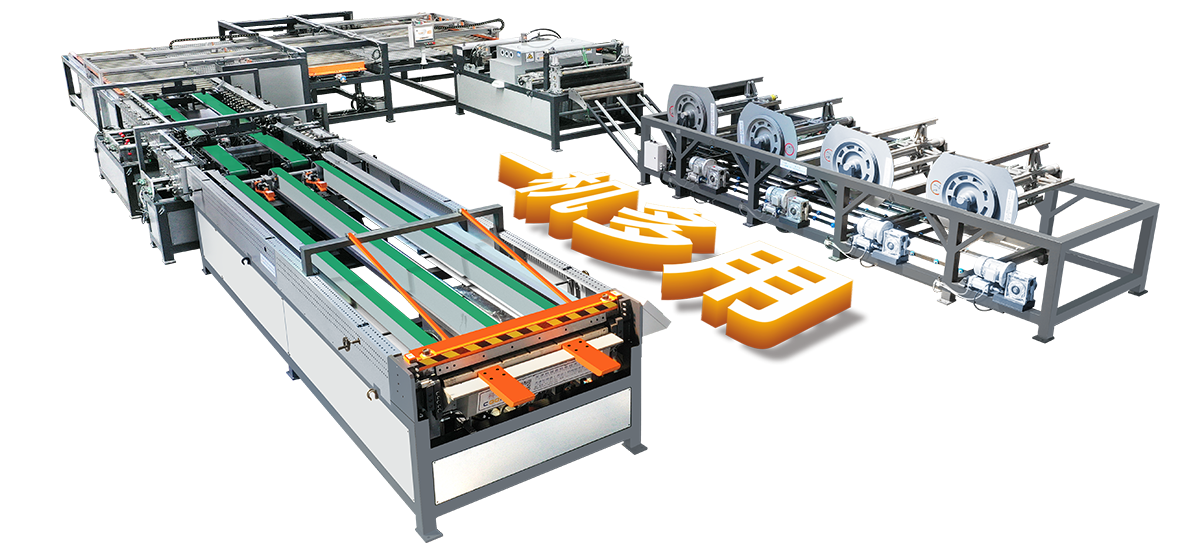

Duct Forming Production Line

-

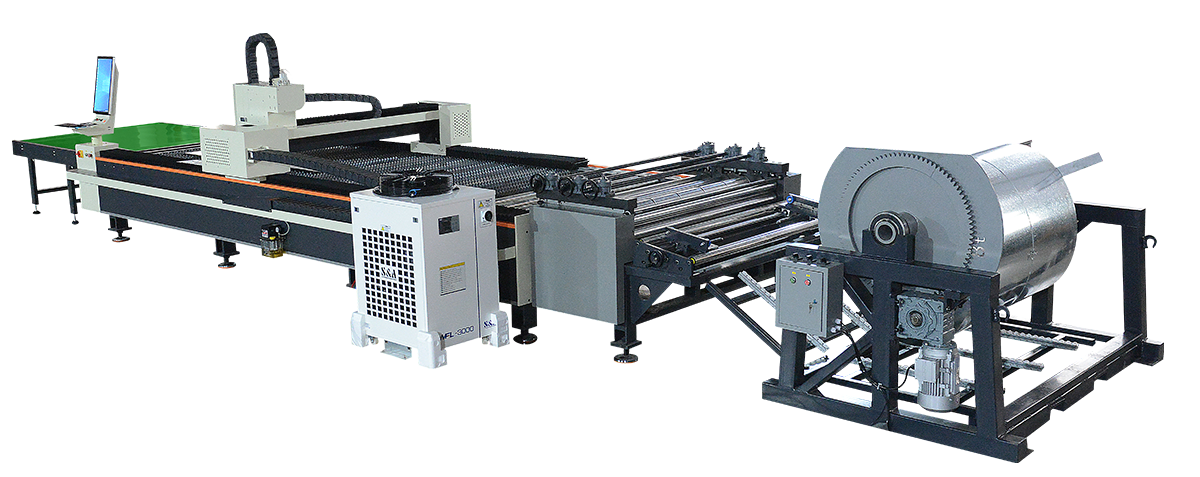

Laser Cutting Machine Series

-

Metal Insulation Pipe Production Line

-

Composite Plate Duct Processing Equipment

-

Flange Machines Series

-

Pittsburgh Lock Forming Machine Series

-

Angle Iron Flange Processing Equipment

-

Square Duct Forming Auxiliary Equipment

-

Round Duct Processing Equipment

-

Damper Processing Equipment

-

Fan Coil Equipment

-

Cable Tray Production Line

-

Fire Hose Production Line

-

Comprehensive Support and Hanger Processing Equipment

-

-

Products

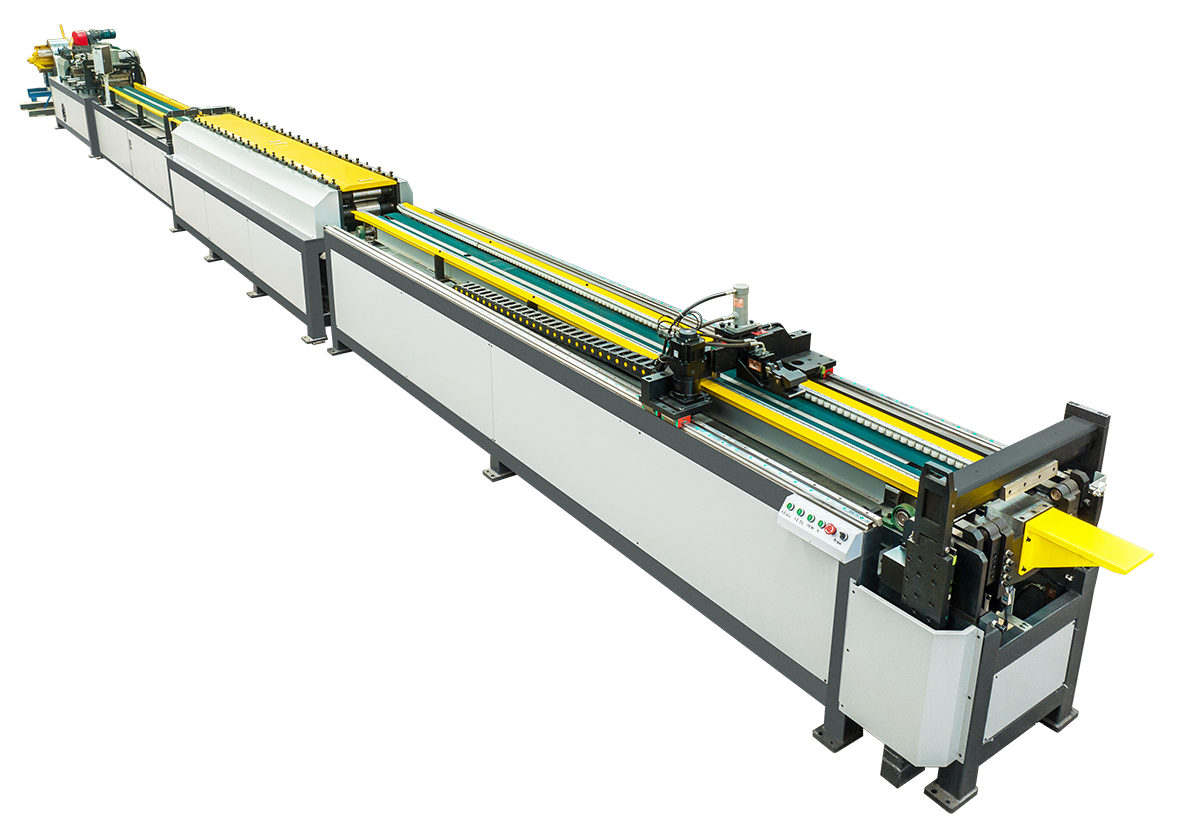

Duct Forming Production Line

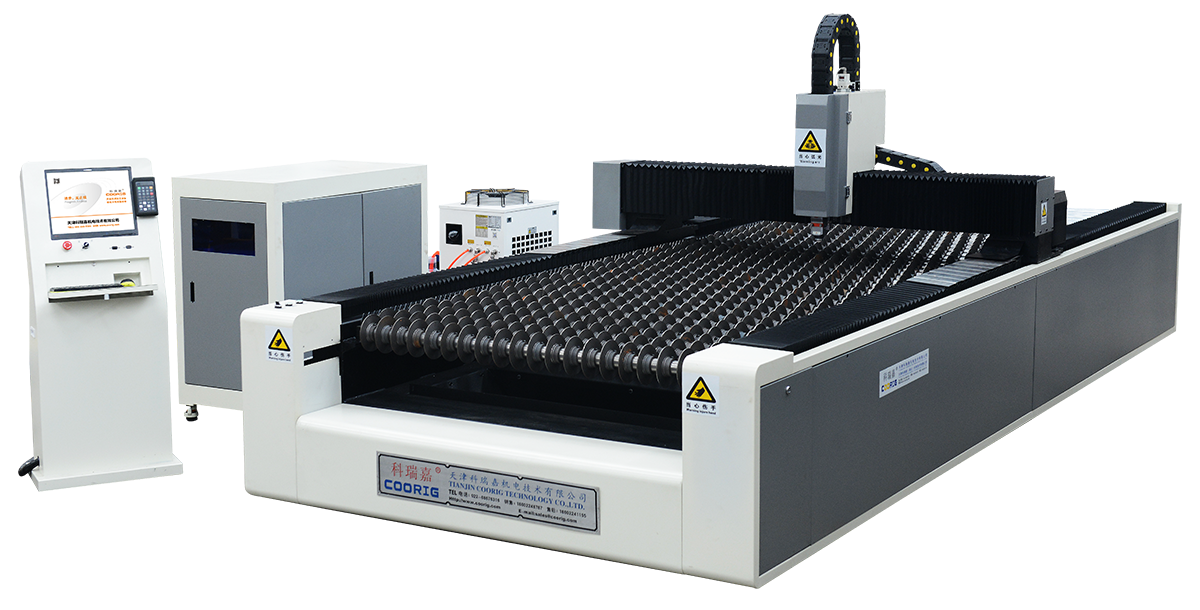

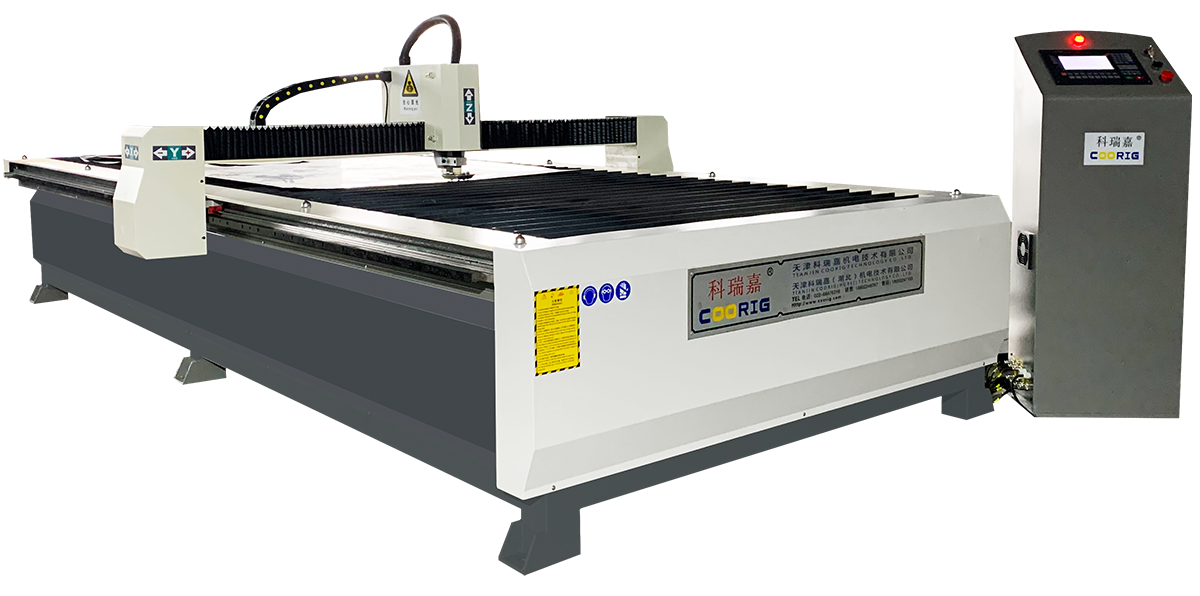

Laser Cutting Machine Series

Metal Insulation Pipe Production Line

Composite Plate Duct Processing Equipment

Flange Machines Series

Pittsburgh Lock Forming Machine Series

Angle Iron Flange Processing Equipment

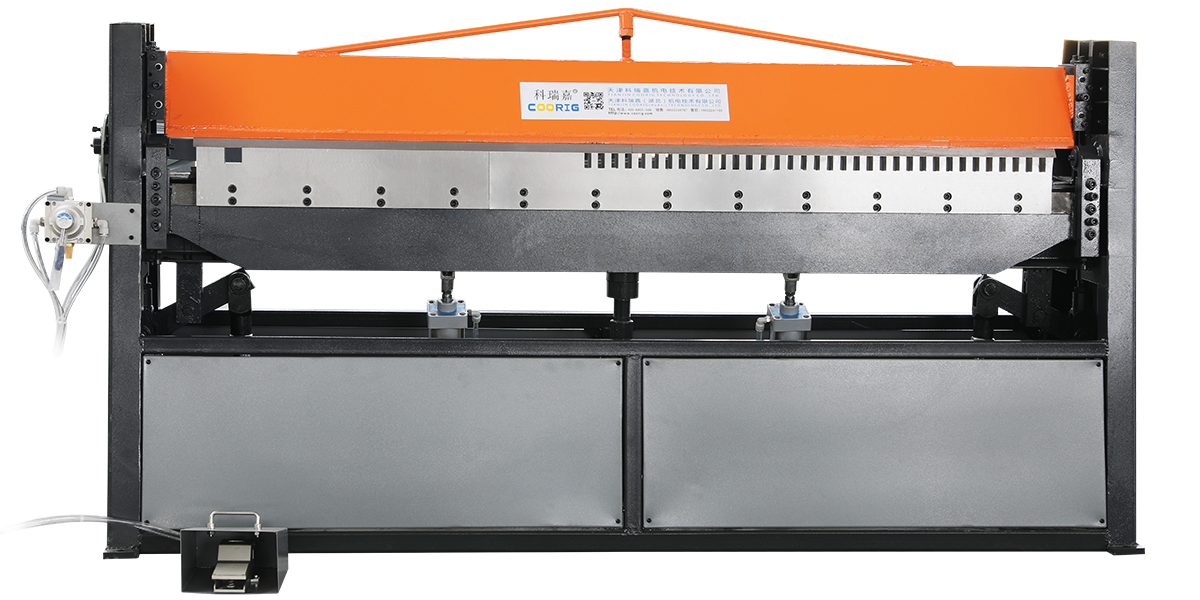

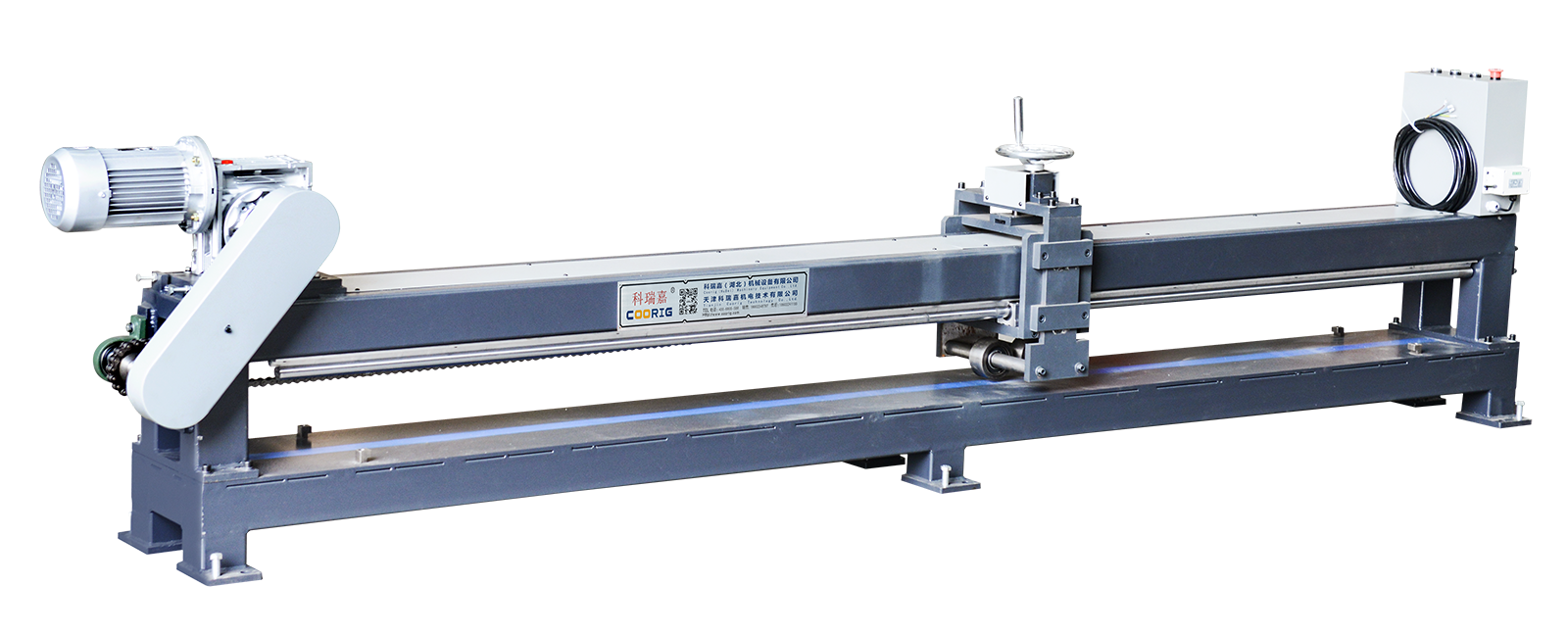

Square Duct Forming Auxiliary Equipment

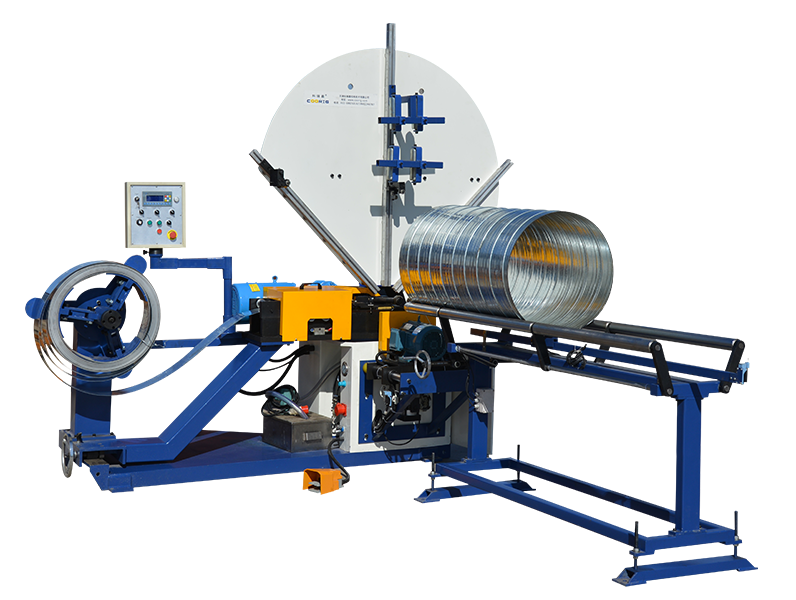

Round Duct Processing Equipment

Damper Processing Equipment

Fan Coil Equipment

Cable Tray Production Line

Fire Hose Production Line

Comprehensive Support and Hanger Processing Equipment

-

Application

-

Services

-

News

-

COORIG

-

Contact

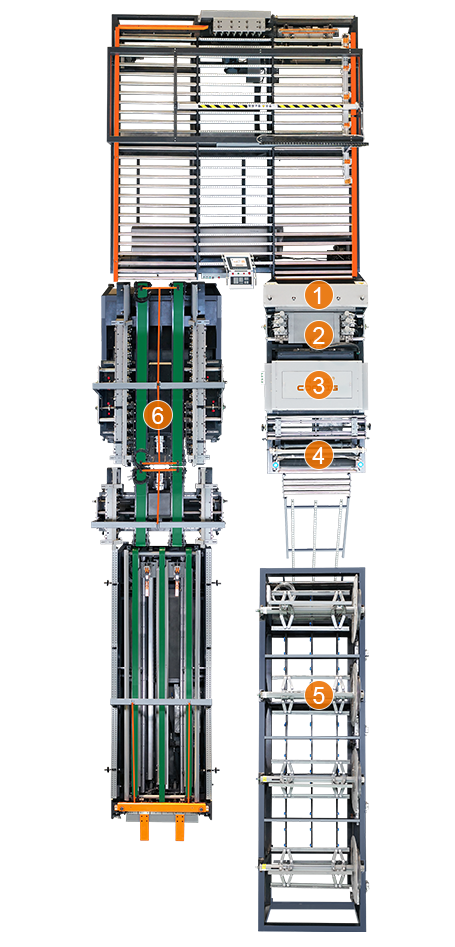

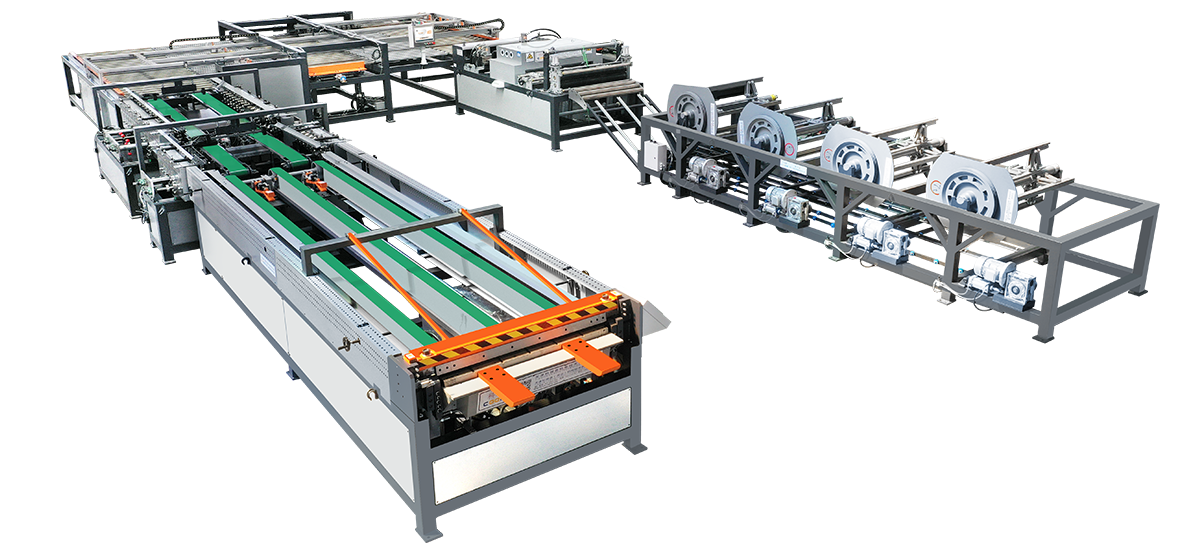

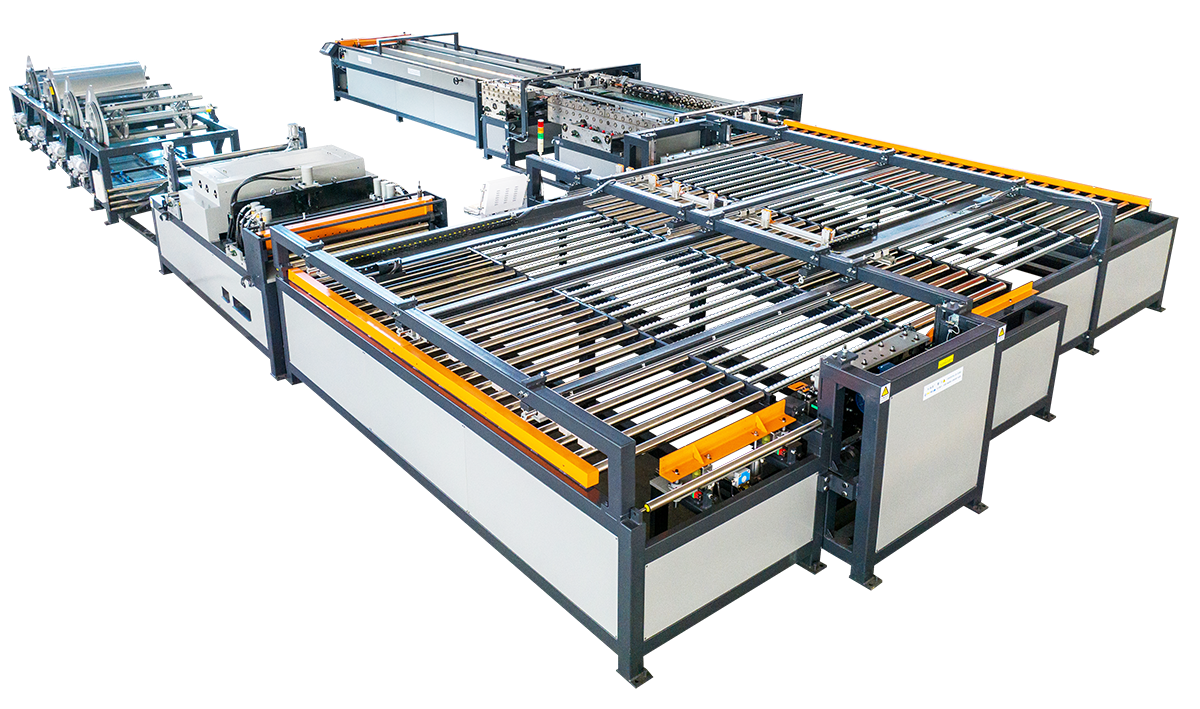

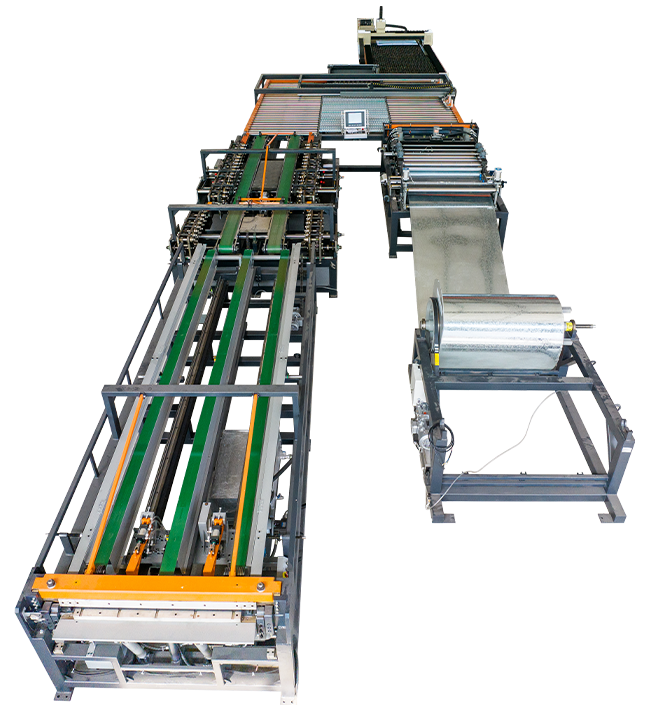

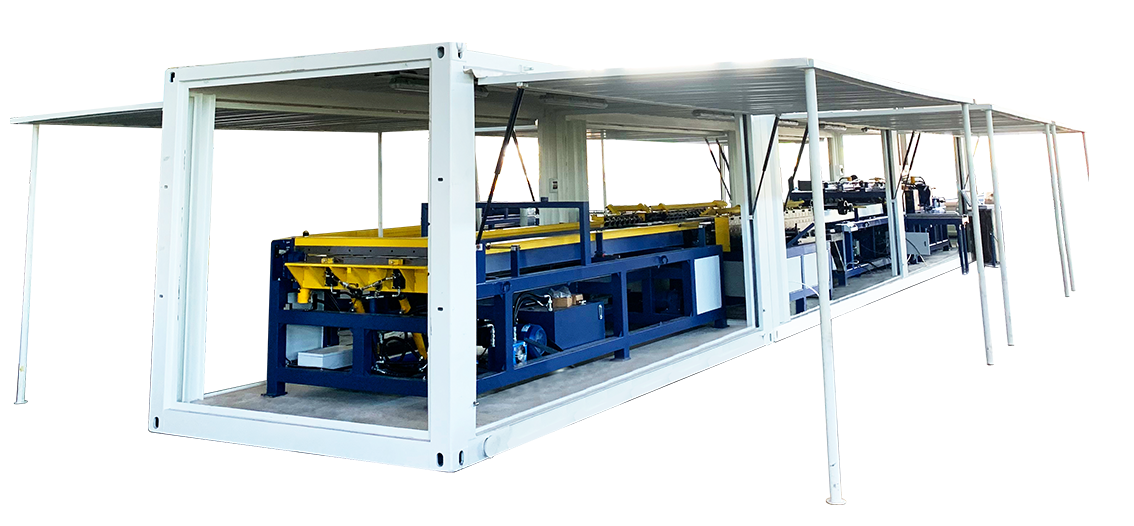

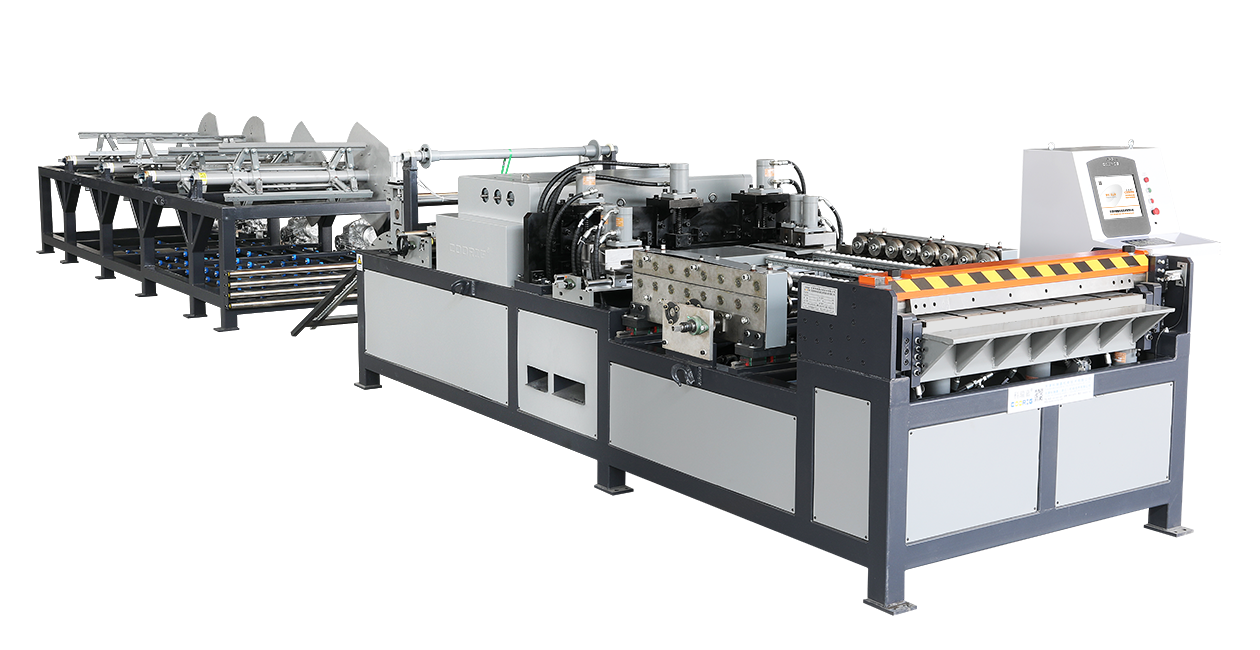

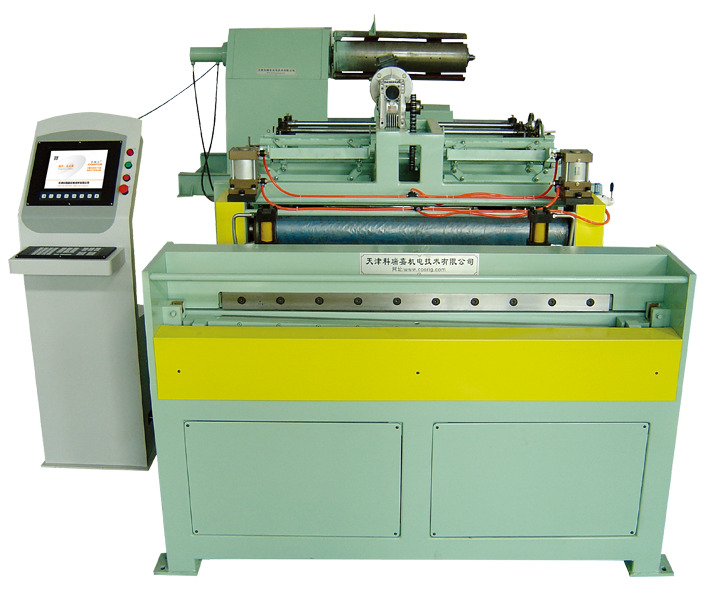

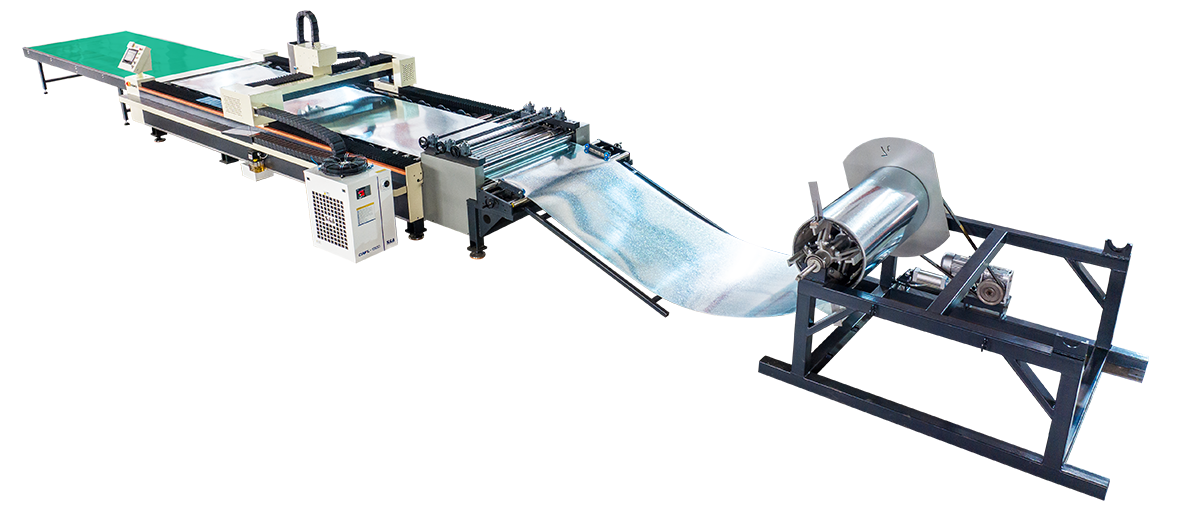

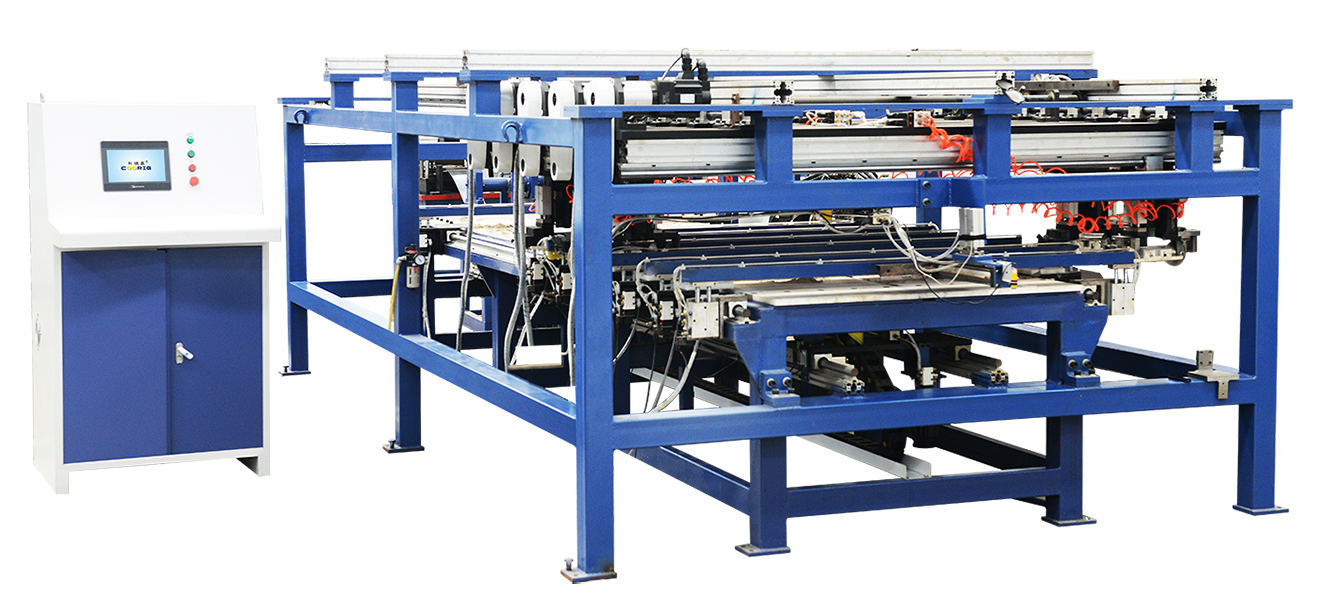

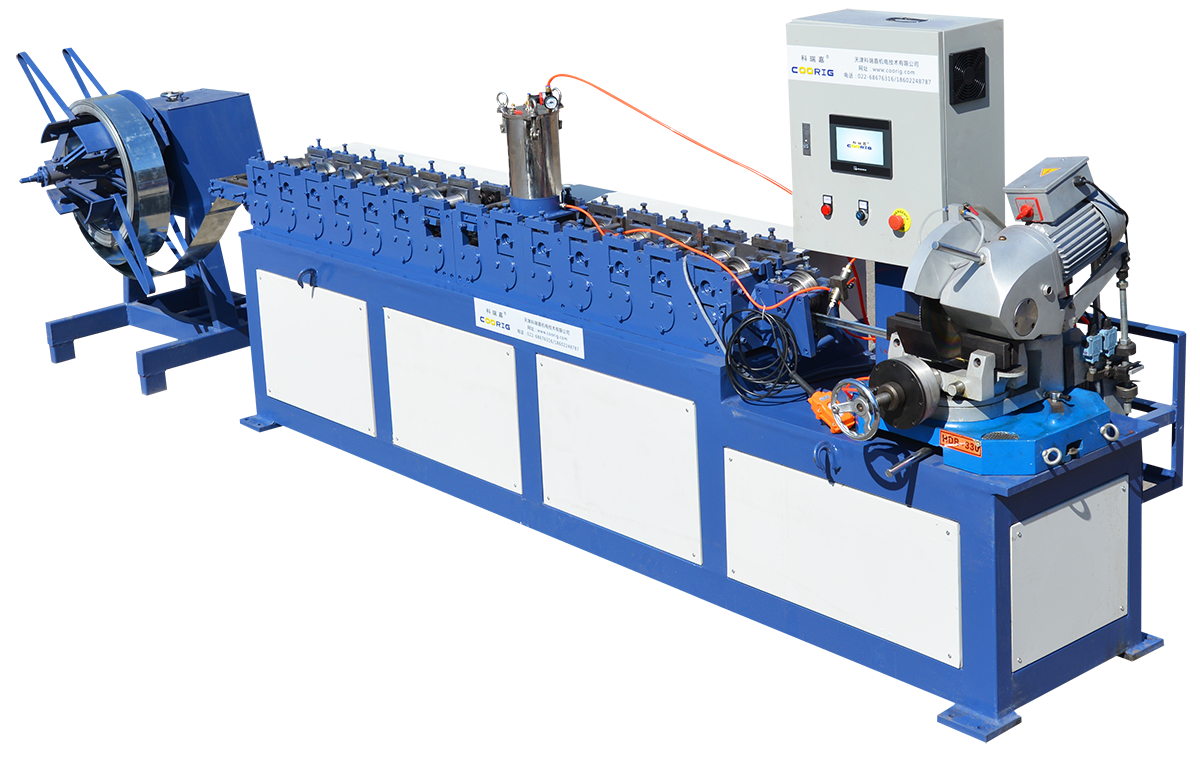

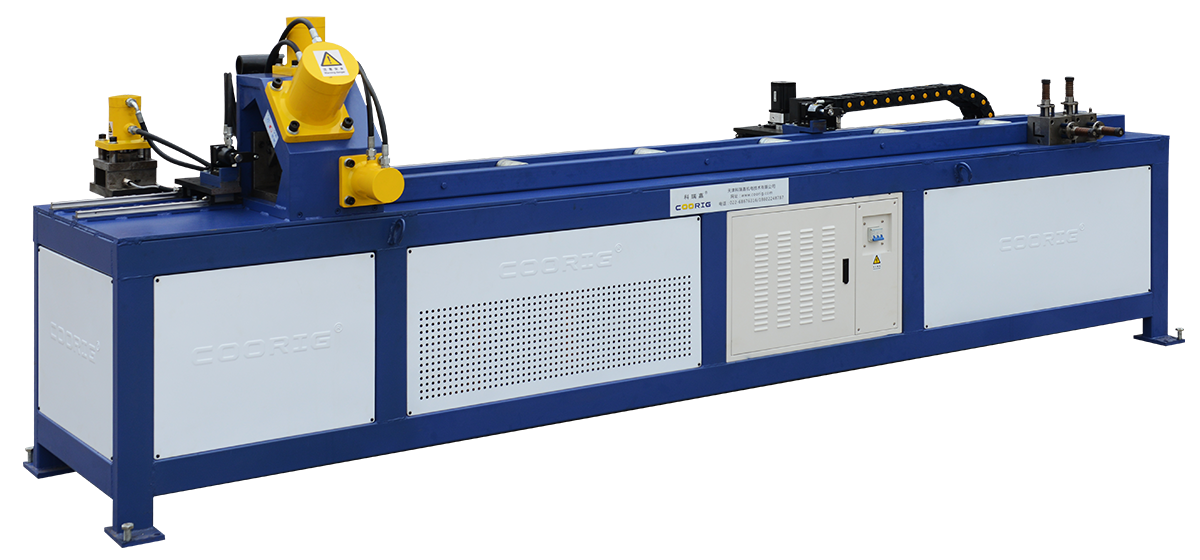

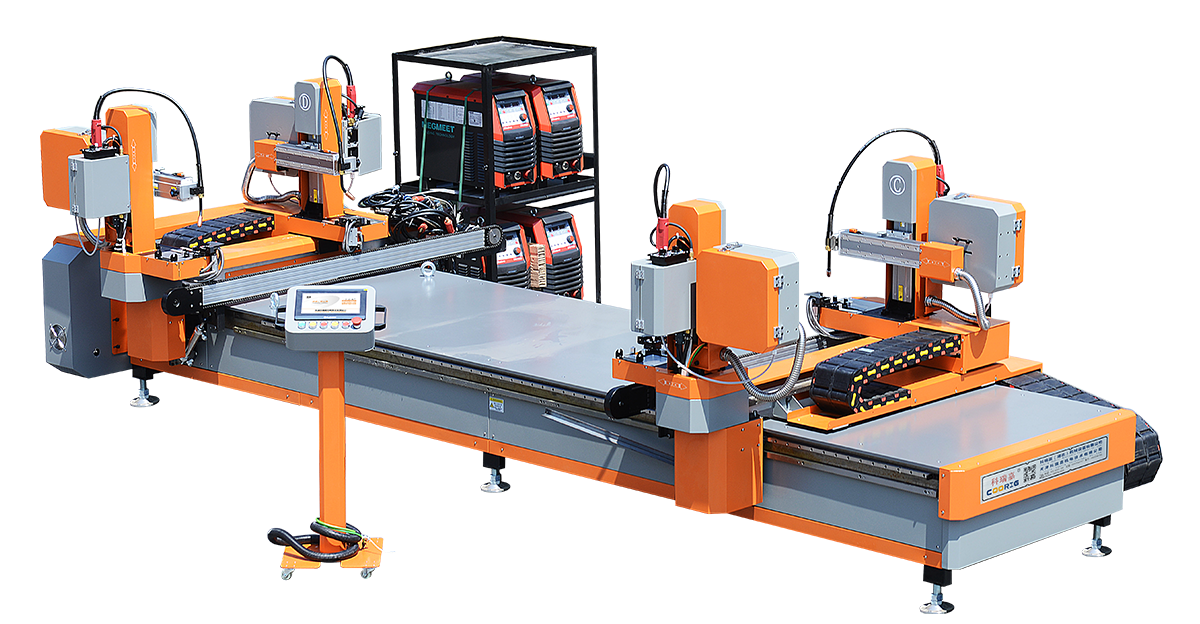

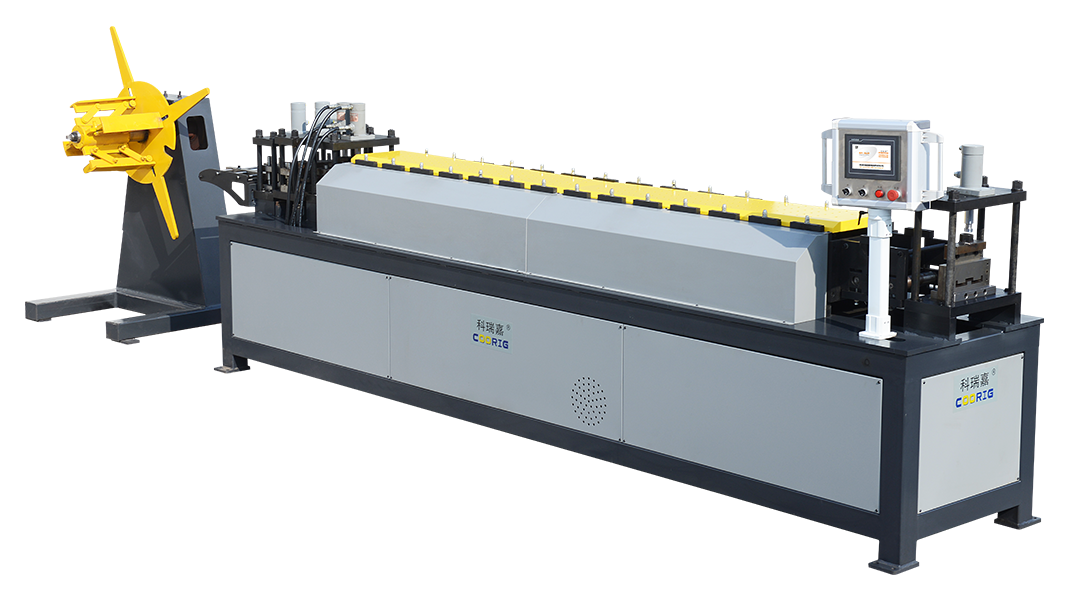

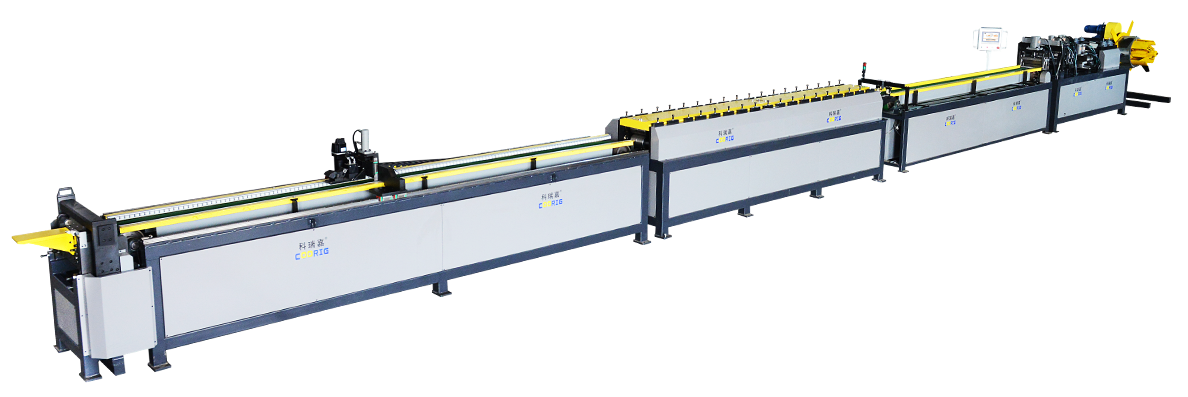

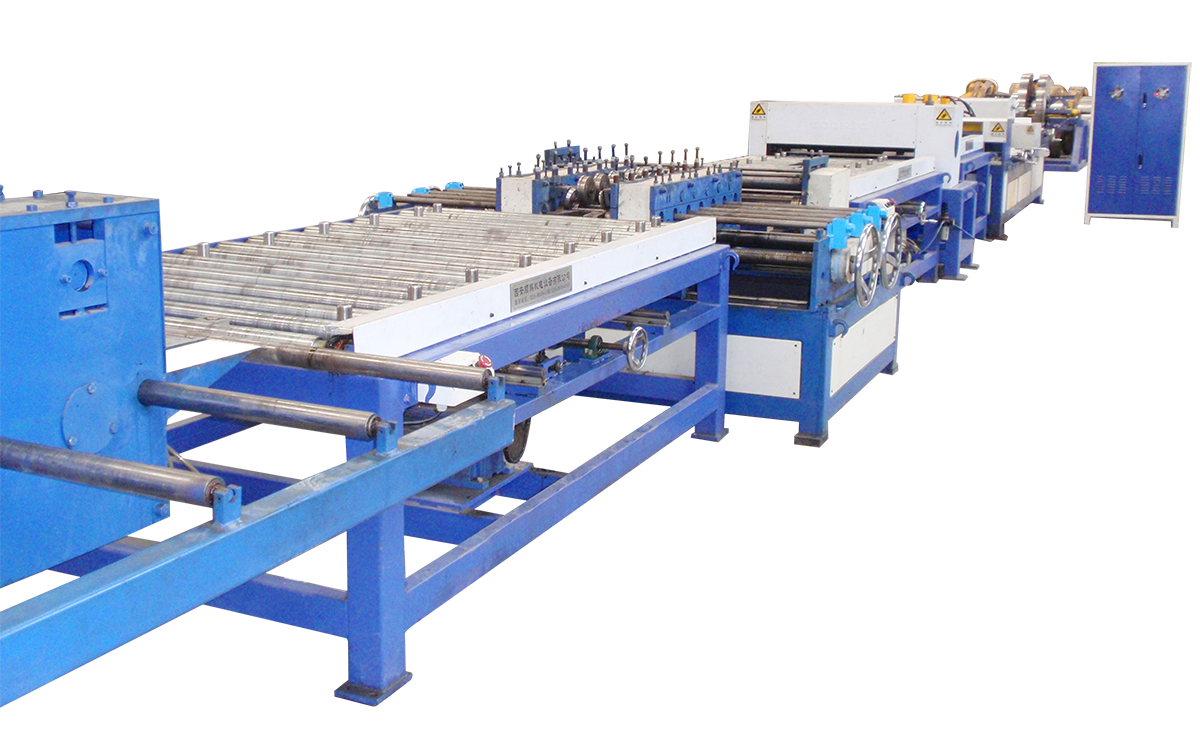

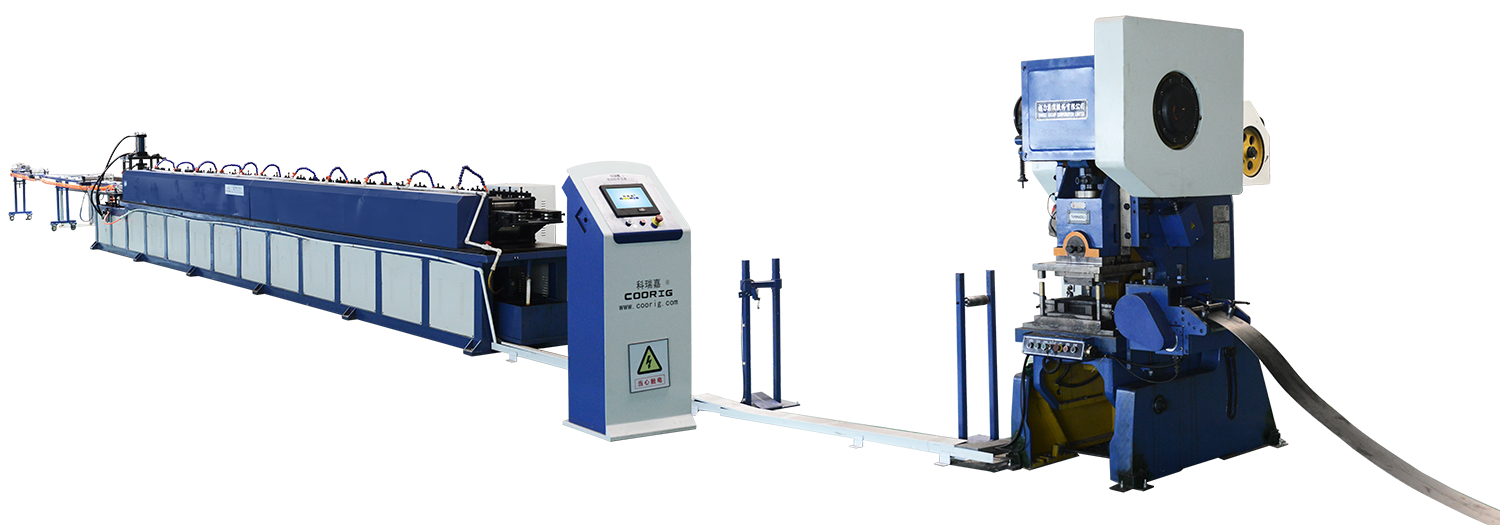

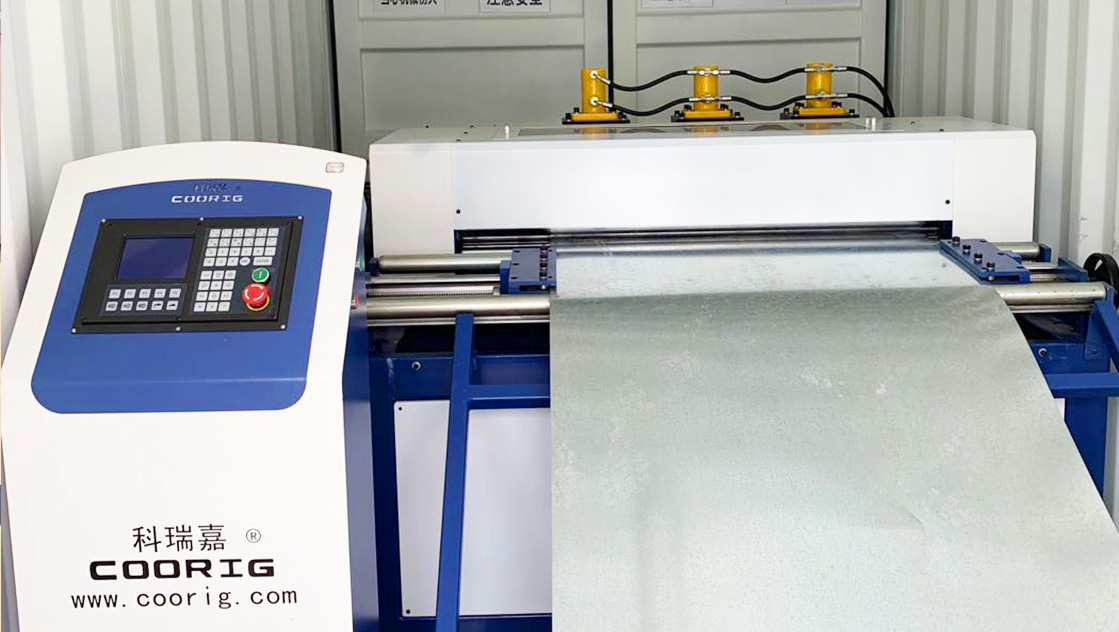

Container Type Mobile Insulated Pipe Processing Station

Uncoiling - Leveling - Punching –Beading- Cutting - Rolling Forming

It can process galvanized sheet, aluminized zinc plate and aluminum plate. It is mainly used in petrochemical engineering, central air conditioning and other pipeline anti-corrosion and thermal insulation outer metal pipe production. Combined with our company's automatic plasma cutting machine and other auxiliary equipment, it can complete the production of special-shaped insulation pipe parts.

特点

1. High degree of automation, computer control, reducing the need for four people to complete a pipeline with traditional way to only one person to operate;

2. The production efficiency is high with an average of 5 pipes per minute;

3. Product consistency is good, rivet hole punching is automatically completed on the production line which is convenient for later onsite installation.

-

Samples

-

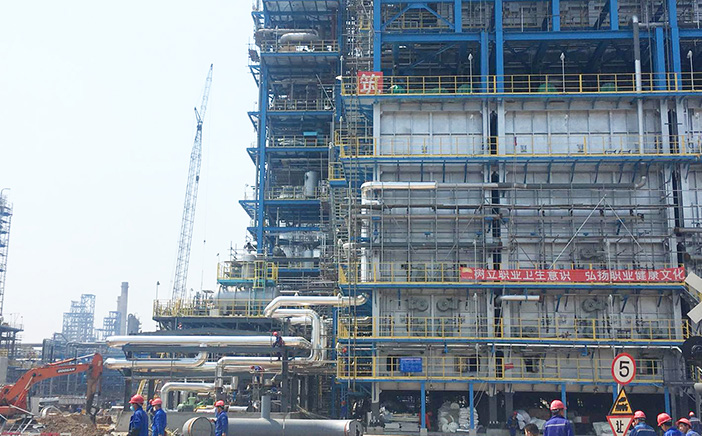

Customer Site

-

Customer Site

MAIN TECHNICAL DATA

|

NO. |

Model |

Thickness

|

Max-width

|

Max-working |

Minimum pipe diameter |

Main processing |

Coiler Max-weight (kg) |

Power |

Dimensions |

Weight |

|

1031

|

BWG-1 | 0.6-1.2 | 1250 | 18 | 180 | Plain carbon steel plate Aluminum plate Aluminized zinc plate |

5000 | 7 | 6000 x1800 x 1700 | 3500 |

|---|---|---|---|---|---|---|---|---|---|---|

|

The equipment appearance, configuration and technical parameters are for reference only, the actual products shall prevail.

|

||||||||||

MORE PRODUCT INFORMATION

-

Customer Site

-

Customer Site

-

Customer Site

-

- HEADQUARTERS

- TIANJIN COORIG TECHNOLOGY CO.,LTD

- Add: Jinghai Developing Zone of Tianjin, China

- Tell: +86 022-68676316 / 68676317 / 68676318

- E-mail: forest@coorig.com

- PRODUCTION BASE

- HUBEI COORIG TECHNOLOGY CO., LTD

- Add: Fengridadao,Developing Zone of Chongyang,Hubei, China

- Tell: +86 0715-3300166 / 3300566

- E-mail: forest@coorig.com

-

- Products

- Duct Forming Production Line

- Laser Cutting Machine Series

- Metal Insulation Pipe Production Line

- Composite Plate Duct Processing Equipment

- Flange Machines Series

- Pittsburgh Lock Forming Machine Series

- Angle Iron Flange Processing Equipment

- Square Duct Forming Auxiliary Equipment

- Round Duct Processing Equipment

- Damper Processing Equipment

- Fan Coil Equipment

- Cable Tray Production Line

- Fire Hose Production Line

- Comprehensive Support and Hanger Processing Equipment

- Services

- After-Sale Service

- Service Network

- Application

- Customer Site

- Video Center

-

WeChat Official Account

-

Mobile Browsings